| Availability: | |

|---|---|

| Quantity: | |

Z2S10-3-3X/ IN010

Rexroth

R983030701

Sandwich plate valve for use in vertical stackings

Porting pattern according to ISO 4401-05-04-0-05 and ISO 4401-05-05-0-05

For the leakage-free blocking of one or two actuator ports, optional

Various cracking pressures

With pre-opening (standard); without pre-opening (optional)

Check valve installation sets available individually

Corrosion-protected design

Sandwich plate valve for use in vertical stackings

Porting pattern according to ISO 4401-05-04-0-05 and ISO 4401-05-05-0-05

For the leakage-free blocking of one or two actuator ports, optional

Various cracking pressures

With pre-opening (standard); without pre-opening (optional)

Check valve installation sets available individually

Corrosion-protected design

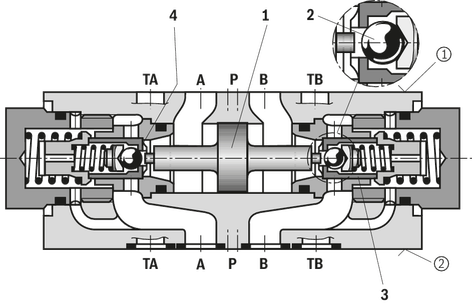

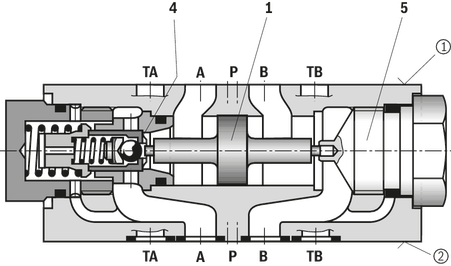

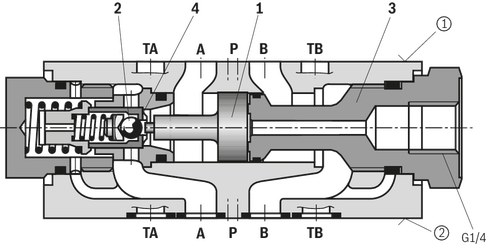

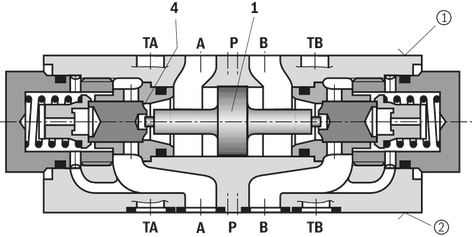

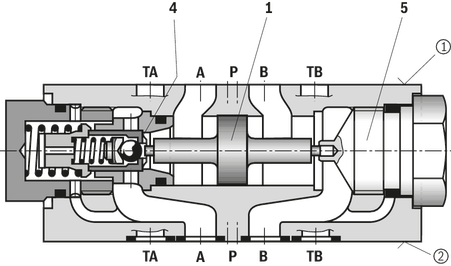

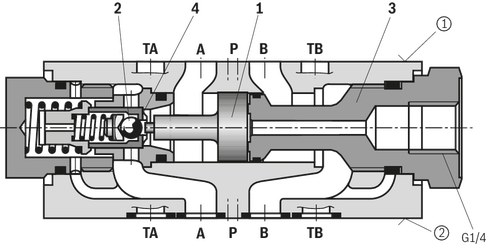

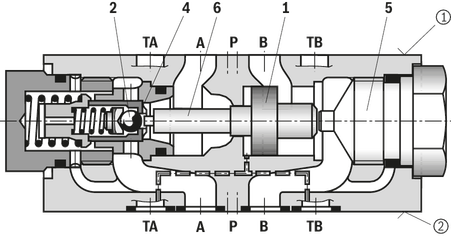

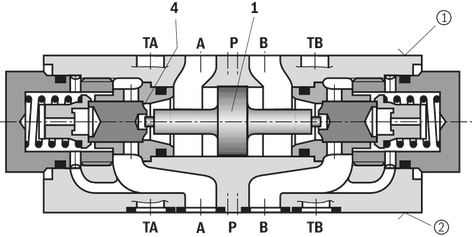

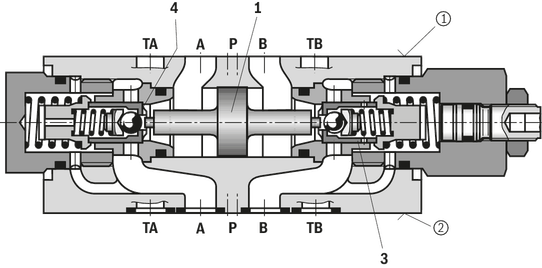

The isolator valve type Z2S is a releasable check valve in sandwich plate design.

It is used for the leakage-free blocking of one or two actuator ports, also in case of longer standstill times.

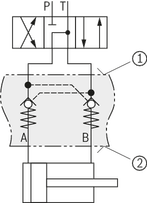

In direction A① to A② or B① to B②, there is a free flow; in the opposite direction, the flow is blocked.

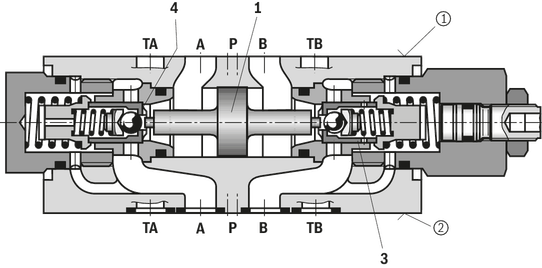

If, for example, there is a flow through the valve in direction A① to A②, the control spool (1) is moved in the direction of the B side, opens the ball seat valve (2) and then pushes the poppet (3) off its seat. Hydraulic fluid can now flow from B➁ to B➀.

In order to allow the ball seat valve (2) to be safely closed, the control spool (1) must be hydraulically unloaded (see circuit example).

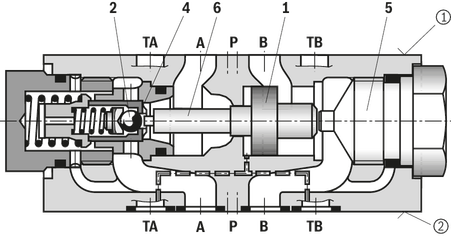

Pre-opening

Due to the pre-opening, there is a damped decompression of the pressurized liquid. Thus, possible switching shocks are avoided.

The two-stage set-up with an increased control open ratio means even low pilot pressure can be unloaded securely.

Type Z2S 10 ‒… (with pre-opening)

Type Z2S 10 ‒…SO41 (without pre-opening)

1 | Control spool, area A2 |

2 | Ball, area A3 |

4 | Poppet, area A1 |

5 | Stop |

6 | Control spool, area A4 |

① | component side |

② | plate side |

Notice:

In valves without pre-opening, sudden unloading of pent-up pressure volume may occur. Resulting switching shocks may lead to premature wear on installed components, as well as noise formation.

Notice:

Deviating from ISO 4401, port T is called TA, port T1 is called TB.

The isolator valve type Z2S is a releasable check valve in sandwich plate design.

It is used for the leakage-free blocking of one or two actuator ports, also in case of longer standstill times.

In direction A① to A② or B① to B②, there is a free flow; in the opposite direction, the flow is blocked.

If, for example, there is a flow through the valve in direction A① to A②, the control spool (1) is moved in the direction of the B side, opens the ball seat valve (2) and then pushes the poppet (3) off its seat. Hydraulic fluid can now flow from B➁ to B➀.

In order to allow the ball seat valve (2) to be safely closed, the control spool (1) must be hydraulically unloaded (see circuit example).

Pre-opening

Due to the pre-opening, there is a damped decompression of the pressurized liquid. Thus, possible switching shocks are avoided.

The two-stage set-up with an increased control open ratio means even low pilot pressure can be unloaded securely.

Type Z2S 10 ‒… (with pre-opening)

Type Z2S 10 ‒…SO41 (without pre-opening)

1 | Control spool, area A2 |

2 | Ball, area A3 |

4 | Poppet, area A1 |

5 | Stop |

6 | Control spool, area A4 |

① | component side |

② | plate side |

Notice:

In valves without pre-opening, sudden unloading of pent-up pressure volume may occur. Resulting switching shocks may lead to premature wear on installed components, as well as noise formation.

Notice:

Deviating from ISO 4401, port T is called TA, port T1 is called TB.

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | ||

Z2S | 10 | – | 3X | / | * |

01 | Check valve, Sandwich plate design | Z2S |

02 | Size 10 | 10 |

Leakage-free blocking | ||

03 | In channel A and B | – |

In channel A | A | |

In channel B | B | |

Cracking pressure | ||

04 | 1,5 bar | 1 |

3 bar | 2 | |

6 bar | 3 | |

10 bar | 4 | |

05 | Component series 30 ... 39 (30 ... 39: unchanged installation and connection dimensions) | 3X |

Corrosion resistance (outside; thick film passivation according to DIN 50979 – Fe//Zn8//Cn//T0) | ||

06 | None (valve housing primed) | no code |

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) | J3 | |

Seal material | ||

07 | NBR seals | no code |

FKM seals | V | |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | ||

Additional pilot oil ports X and Y 1) | ||

08 | Without X and Y | no code |

With X and Y | XY | |

Spool position monitoring 2) | ||

09 | Without position switch | no code |

- Inductive position switch type QM (Version "3" only) | ||

Monitored spool position "a" | QMA | |

Monitored spool position "b" | QMB | |

Special version | ||

10 | Without | no code |

Check valve with stroke limitation | SO14 | |

Control open by external port G1/4 (only version "A" and "B") | SO40 | |

Without pre-opening | SO41 | |

Control spool unloaded to port T | SO60 | |

With pre-opening and control open from channel P | SO150 | |

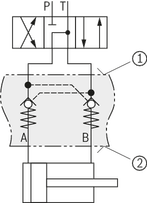

Symbols (examples) see "Symbols/Circuit diagrams" | ||

11 | Further details in the plain text | * |

| 1) | With version "SO150", ports X and Y are already in place. (No ordering code required) |

| 2) | Only with version "3" (cracking pressure 6 bar) and on side with leakage-free blocking. E.g. Z2S 10 A3-3X/QMA |

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | ||

Z2S | 10 | – | 3X | / | * |

01 | Check valve, Sandwich plate design | Z2S |

02 | Size 10 | 10 |

Leakage-free blocking | ||

03 | In channel A and B | – |

In channel A | A | |

In channel B | B | |

Cracking pressure | ||

04 | 1,5 bar | 1 |

3 bar | 2 | |

6 bar | 3 | |

10 bar | 4 | |

05 | Component series 30 ... 39 (30 ... 39: unchanged installation and connection dimensions) | 3X |

Corrosion resistance (outside; thick film passivation according to DIN 50979 – Fe//Zn8//Cn//T0) | ||

06 | None (valve housing primed) | no code |

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) | J3 | |

Seal material | ||

07 | NBR seals | no code |

FKM seals | V | |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | ||

Additional pilot oil ports X and Y 1) | ||

08 | Without X and Y | no code |

With X and Y | XY | |

Spool position monitoring 2) | ||

09 | Without position switch | no code |

- Inductive position switch type QM (Version "3" only) | ||

Monitored spool position "a" | QMA | |

Monitored spool position "b" | QMB | |

Special version | ||

10 | Without | no code |

Check valve with stroke limitation | SO14 | |

Control open by external port G1/4 (only version "A" and "B") | SO40 | |

Without pre-opening | SO41 | |

Control spool unloaded to port T | SO60 | |

With pre-opening and control open from channel P | SO150 | |

Symbols (examples) see "Symbols/Circuit diagrams" | ||

11 | Further details in the plain text | * |

| 1) | With version "SO150", ports X and Y are already in place. (No ordering code required) |

| 2) | Only with version "3" (cracking pressure 6 bar) and on side with leakage-free blocking. E.g. Z2S 10 A3-3X/QMA |

Size | 10 | ||

Weight | kg | 3 | |

Installation position | any | ||

Ambient temperature range | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Size | 10 | ||

Maximum operating pressure | bar | 315 | |

Cracking pressure (in free direction) | See characteristic curves | ||

Maximum flow | l/min | 120 | |

Direction of flow | see symbols | ||

Hydraulic fluid | see table "Hydraulic fluid" | ||

Hydraulic fluid temperature range (at the valve working ports) | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Viscosity range | mm²/s | 2.8 … 500 | |

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) | Class 20/18/15 | ||

Area ratio | Without pre-opening | A1/A2 ~ 1/3 (see sectional drawing) | |

With pre-opening | A3/A2 ~ 1/11,5 (see sectional drawing) | ||

Version "SO60" | A1/A4 ~ 1/6 (see sectional drawing) | ||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP, HLPD, HVLP, HVLPD | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable | Insoluble in water | HETG | NBR, FKM | ISO 15380 | 90221 |

HEES | FKM | ||||

Soluble in water | HEPG | FKM | ISO 15380 | ||

Flame-resistant | Water-free | HFDU, HFDR | FKM | ISO 12922 | 90222 |

Containing water | HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) | NBR | ISO 12922 | 90223 | |

Important information on hydraulic fluids:

| |||||

Notice:

Selection of optimal sealing material (see "Type code") also depends on the type of hydraulic fluid used.

Size | 10 | ||

Weight | kg | 3 | |

Installation position | any | ||

Ambient temperature range | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Size | 10 | ||

Maximum operating pressure | bar | 315 | |

Cracking pressure (in free direction) | See characteristic curves | ||

Maximum flow | l/min | 120 | |

Direction of flow | see symbols | ||

Hydraulic fluid | see table "Hydraulic fluid" | ||

Hydraulic fluid temperature range (at the valve working ports) | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Viscosity range | mm²/s | 2.8 … 500 | |

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) | Class 20/18/15 | ||

Area ratio | Without pre-opening | A1/A2 ~ 1/3 (see sectional drawing) | |

With pre-opening | A3/A2 ~ 1/11,5 (see sectional drawing) | ||

Version "SO60" | A1/A4 ~ 1/6 (see sectional drawing) | ||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP, HLPD, HVLP, HVLPD | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable | Insoluble in water | HETG | NBR, FKM | ISO 15380 | 90221 |

HEES | FKM | ||||

Soluble in water | HEPG | FKM | ISO 15380 | ||

Flame-resistant | Water-free | HFDU, HFDR | FKM | ISO 12922 | 90222 |

Containing water | HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) | NBR | ISO 12922 | 90223 | |

Important information on hydraulic fluids:

| |||||

Notice:

Selection of optimal sealing material (see "Type code") also depends on the type of hydraulic fluid used.

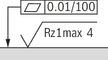

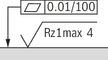

Dimensions in mm

|

Required surface quality of the valve contact surface |

Type | L1 | L2 |

mm | mm | |

| Z2S 10 ...ohne Bez. | 13.5 | 13.5 |

| Z2S 10 ...SO14 | 13.5 | 38.5 |

| Z2S 10 A...SO40 | 6.5 | 13.5 |

| Z2S 10 B...SO40 | 13.5 | 6.5 |

| Z2S 10 ...SO41 | 13.5 | 13.5 |

| Z2S 10 ...SO60 | 13.5 | 13.5 |

| Z2S 10 ...SO150 | 13.5 | 13.5 |

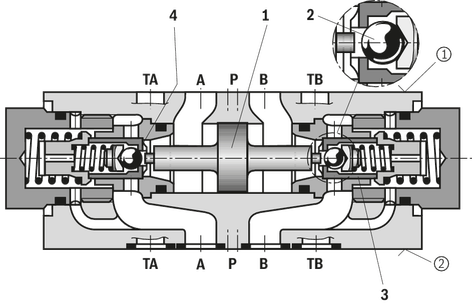

① | component side |

② | plate side |

1 | Name plate |

2 | Through hole for valve mounting |

3 | Identical seal rings for ports A, B, P, TA and TB |

4 | Plug screw SW30, tightening torque MA = 40+5 Nm |

5.1 | Version with position switch “QMA” (for circuitry refer to "Electrical connection") |

5.2 | Version with position switch “QMB” (for circuitry refer to "Electrical connection") |

6 | Porting pattern according to ISO 4401-05-04-0-05, ISO 4401-05-05-0-05; deviating from ISO 4401, port T is referred to with TA and port T1 is referred to with TB in this data sheet. |

Size | Quantity | Hexagon socket head cap screws | Material number |

10 | 4 | ISO 4762 - M6 10.9 | - |

Notice:

Length and tightening torque of the valve mounting screws must be calculated according to the components mounted under and over the sandwich plate valve.

Dimensions in mm

|

Required surface quality of the valve contact surface |

Type | L1 | L2 |

mm | mm | |

| Z2S 10 ...ohne Bez. | 13.5 | 13.5 |

| Z2S 10 ...SO14 | 13.5 | 38.5 |

| Z2S 10 A...SO40 | 6.5 | 13.5 |

| Z2S 10 B...SO40 | 13.5 | 6.5 |

| Z2S 10 ...SO41 | 13.5 | 13.5 |

| Z2S 10 ...SO60 | 13.5 | 13.5 |

| Z2S 10 ...SO150 | 13.5 | 13.5 |

① | component side |

② | plate side |

1 | Name plate |

2 | Through hole for valve mounting |

3 | Identical seal rings for ports A, B, P, TA and TB |

4 | Plug screw SW30, tightening torque MA = 40+5 Nm |

5.1 | Version with position switch “QMA” (for circuitry refer to "Electrical connection") |

5.2 | Version with position switch “QMB” (for circuitry refer to "Electrical connection") |

6 | Porting pattern according to ISO 4401-05-04-0-05, ISO 4401-05-05-0-05; deviating from ISO 4401, port T is referred to with TA and port T1 is referred to with TB in this data sheet. |

Size | Quantity | Hexagon socket head cap screws | Material number |

10 | 4 | ISO 4762 - M6 10.9 | - |

Notice:

Length and tightening torque of the valve mounting screws must be calculated according to the components mounted under and over the sandwich plate valve.