| Availability: | |

|---|---|

| Quantity: | |

Z2FS 16-8-3X/S

Rexroth

Sandwich plate valve

Porting pattern according to ISO 4401-07-07-0-05

Flow limitation of 2 actuator ports

Adjustment type: Spindle with hexagon socket

Meter-in or meter-out throttling

Sandwich plate valve

Porting pattern according to ISO 4401-07-07-0-05

Flow limitation of 2 actuator ports

Adjustment type: Spindle with hexagon socket

Meter-in or meter-out throttling

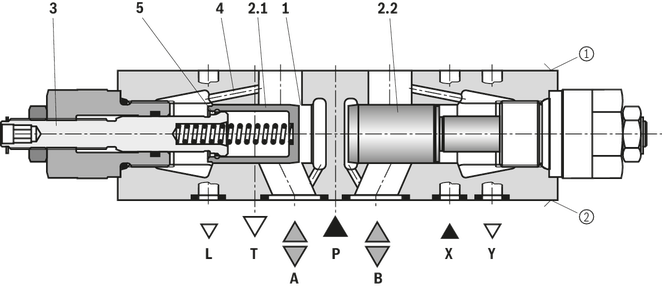

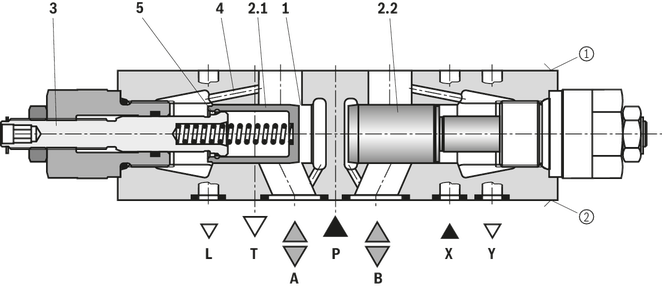

The valve type Z2FS is a throttle check valve in sandwich plate design. It is used for the flow limitation of one or two actuator ports.

Two symmetrically arranged throttle check valves limit flows (by adjustable throttle spools) in one direction and allow free return flow in the opposite direction.

In case of supply throttling, the hydraulic fluid is directed through channel A➀ via throttling point (1) to actuator A➁. The throttle spool (2.1) can be axially adjusted via the spindle (3) for adjustment of the throttling point (1).

Simultaneously, the hydraulic fluid in channel A➀ is directed via the bore (4) to the piston side (5).

The active pressure and the spring force retain the throttle spool (2.1) in throttle position.

The hydraulic fluid return flow from actuator B➁ displaces the throttle spool (2.2) and enables the unobstructed flow as check valve. Depending on the version ("S" or "S2"), the throttling effect may occur in supply or discharge.

Flow limitation

For actuator velocity adjustment, the throttle check valve is installed between the directional valve and the subplate.

Supply throttling

➀ | component side |

➁ | plate side |

The valve type Z2FS is a throttle check valve in sandwich plate design. It is used for the flow limitation of one or two actuator ports.

Two symmetrically arranged throttle check valves limit flows (by adjustable throttle spools) in one direction and allow free return flow in the opposite direction.

In case of supply throttling, the hydraulic fluid is directed through channel A➀ via throttling point (1) to actuator A➁. The throttle spool (2.1) can be axially adjusted via the spindle (3) for adjustment of the throttling point (1).

Simultaneously, the hydraulic fluid in channel A➀ is directed via the bore (4) to the piston side (5).

The active pressure and the spring force retain the throttle spool (2.1) in throttle position.

The hydraulic fluid return flow from actuator B➁ displaces the throttle spool (2.2) and enables the unobstructed flow as check valve. Depending on the version ("S" or "S2"), the throttling effect may occur in supply or discharge.

Flow limitation

For actuator velocity adjustment, the throttle check valve is installed between the directional valve and the subplate.

Supply throttling

➀ | component side |

➁ | plate side |

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | ||

Z | 2 | FS | 16 | 8 | – | 3X | / | * |

01 | Sandwich plate valve | Z |

Number of functions | ||

02 | 2 (throttling in channel A and/or B) | 2 |

03 | Throttle check valve | FS |

04 | Size 16 | 16 |

Functions in | ||

05 | Channel A | A |

Channel B | B | |

Channel A and B | – | |

Adjustment type | ||

06 | Spindle with internal hexagon | 8 |

07 | Component series 30 ... 39 (30 ... 39: unchanged installation and connection dimensions) | 3X |

Supply throttling / discharge throttling | ||

08 | Supply throttling on side A ("…A8–3X/S") | S |

Supply throttling on side B ("…B8–3X/S") | ||

Supply throttling on side A and B ("…–8–3X/S") | ||

Discharge throttling on side A ("…A8–3X/S2") | S2 | |

Discharge throttling on side B ("…B8–3X/S2") | ||

Discharge throttling on side A and B ("…–8–3X/S2") | ||

Corrosion resistance (outside) | ||

09 | None (valve housing primed) (standard) | no code |

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) | J3 | |

Seal material | ||

10 | NBR seals | no code |

FKM seals | V | |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | ||

11 | Further details in the plain text | * |

Preferred types and standard units are contained in the EPS (standard price list).

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | ||

Z | 2 | FS | 16 | 8 | – | 3X | / | * |

01 | Sandwich plate valve | Z |

Number of functions | ||

02 | 2 (throttling in channel A and/or B) | 2 |

03 | Throttle check valve | FS |

04 | Size 16 | 16 |

Functions in | ||

05 | Channel A | A |

Channel B | B | |

Channel A and B | – | |

Adjustment type | ||

06 | Spindle with internal hexagon | 8 |

07 | Component series 30 ... 39 (30 ... 39: unchanged installation and connection dimensions) | 3X |

Supply throttling / discharge throttling | ||

08 | Supply throttling on side A ("…A8–3X/S") | S |

Supply throttling on side B ("…B8–3X/S") | ||

Supply throttling on side A and B ("…–8–3X/S") | ||

Discharge throttling on side A ("…A8–3X/S2") | S2 | |

Discharge throttling on side B ("…B8–3X/S2") | ||

Discharge throttling on side A and B ("…–8–3X/S2") | ||

Corrosion resistance (outside) | ||

09 | None (valve housing primed) (standard) | no code |

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) | J3 | |

Seal material | ||

10 | NBR seals | no code |

FKM seals | V | |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | ||

11 | Further details in the plain text | * |

Preferred types and standard units are contained in the EPS (standard price list).

Size | 16 | ||

Weight (approx.) | kg | 4.7 | |

Installation position | any | ||

Ambient temperature range | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Size | 16 | ||

Maximum operating pressure | bar | 350 | |

Maximum flow | l/min | 250 | |

Hydraulic fluid | see table | ||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Viscosity range | mm²/s | 2.8 … 380 | |

Maximum admissible degree of contamination of the hydraulic fluid 1) | Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable | Insoluble in water | HEES 2) | FKM |

ISO 15380 | 90221 |

Soluble in water | HEPG 2) | FKM |

ISO 15380 | ||

Containing water | Containing water | HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) 2) |

NBR | ISO 12922 | upon request |

Important information on hydraulic fluids:

Flame-resistant – containing water:

| |||||

| 2) Not for version "J3" |

Size | 16 | ||

Weight (approx.) | kg | 4.7 | |

Installation position | any | ||

Ambient temperature range | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Size | 16 | ||

Maximum operating pressure | bar | 350 | |

Maximum flow | l/min | 250 | |

Hydraulic fluid | see table | ||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Viscosity range | mm²/s | 2.8 … 380 | |

Maximum admissible degree of contamination of the hydraulic fluid 1) | Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable | Insoluble in water | HEES 2) | FKM |

ISO 15380 | 90221 |

Soluble in water | HEPG 2) | FKM |

ISO 15380 | ||

Containing water | Containing water | HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) 2) |

NBR | ISO 12922 | upon request |

Important information on hydraulic fluids:

Flame-resistant – containing water:

| |||||

| 2) Not for version "J3" |

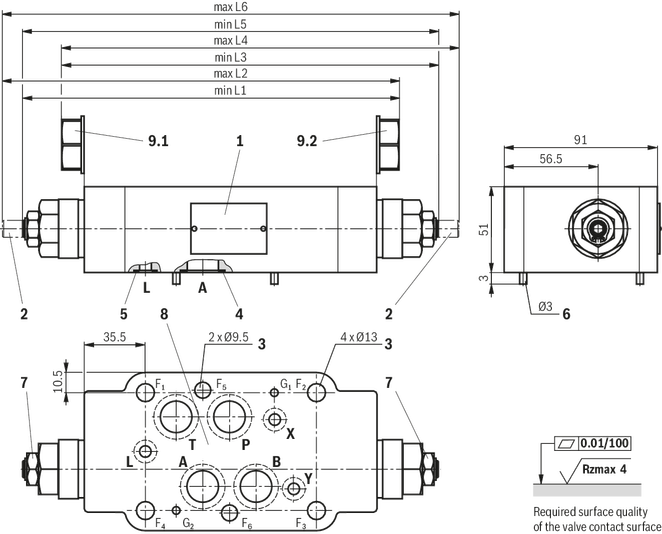

Dimensions in mm

Dimensions in mm

1 | Name plate |

2 | Adjustment type "8“ Spindle for changing the flow cross-section (internal hexagon SW6)

|

3 | Through holes for valve mounting |

4 | Identical seal rings for ports A, B, P, T |

5 | Identical seal rings for ports X, Y, L |

6 | Locking pin (included in the scope of delivery) |

7 | Hexagon SW19, tightening torque MA see table |

8 | Porting pattern according to ISO 4401-07-07-0-05 |

9.1 | Plug screw with version "B" |

9.2 | Plug screw with version "A" |

Version “Corrosion resistance” | L1 | L2 | L3 | L4 | L5 | L6 | Pos. 7 MA in Nm ±10 % |

mm | mm | mm | mm | mm | mm | Nm | |

| "no code" | 224 | 248 | 224 | 248 | 246 | 294 | 25 |

| „J3“ | 227 | 251 | 227 | 251 | 252 | 300 | 33 |

Valve mounting screws (separate order)

metric

4 hexagon socket head cap screws ISO 4762 - M10 - 10.9-flZn-240h-L

2 hexagon socket head cap screws ISO 4762 - M6 - 10.9-flZn-240h-L

UNC

4 hexagon socket head cap screws 3/8-16 UNC

2 hexagon socket head cap screws 1/4-20 UNC

Notice:

Length and tightening torque of the valve mounting screws must be calculated according to the components mounted under and over the sandwich plate valve.

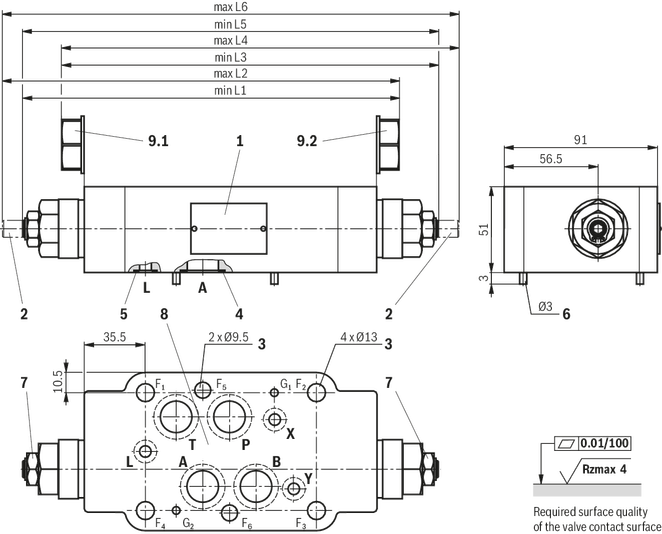

Dimensions in mm

Dimensions in mm

1 | Name plate |

2 | Adjustment type "8“ Spindle for changing the flow cross-section (internal hexagon SW6)

|

3 | Through holes for valve mounting |

4 | Identical seal rings for ports A, B, P, T |

5 | Identical seal rings for ports X, Y, L |

6 | Locking pin (included in the scope of delivery) |

7 | Hexagon SW19, tightening torque MA see table |

8 | Porting pattern according to ISO 4401-07-07-0-05 |

9.1 | Plug screw with version "B" |

9.2 | Plug screw with version "A" |

Version “Corrosion resistance” | L1 | L2 | L3 | L4 | L5 | L6 | Pos. 7 MA in Nm ±10 % |

mm | mm | mm | mm | mm | mm | Nm | |

| "no code" | 224 | 248 | 224 | 248 | 246 | 294 | 25 |

| „J3“ | 227 | 251 | 227 | 251 | 252 | 300 | 33 |

Valve mounting screws (separate order)

metric

4 hexagon socket head cap screws ISO 4762 - M10 - 10.9-flZn-240h-L

2 hexagon socket head cap screws ISO 4762 - M6 - 10.9-flZn-240h-L

UNC

4 hexagon socket head cap screws 3/8-16 UNC

2 hexagon socket head cap screws 1/4-20 UNC

Notice:

Length and tightening torque of the valve mounting screws must be calculated according to the components mounted under and over the sandwich plate valve.