| Availability: | |

|---|---|

| Quantity: | |

MG 10 G1X/V

Rexroth

R900422145

For pipeline installation

Related to pressure and viscosity

Throttling in both directions of flow

Corrosion-protected design

For pipeline installation

Related to pressure and viscosity

Throttling in both directions of flow

Corrosion-protected design

The valves type MG are pressure- and viscosity-dependent throttle valves.

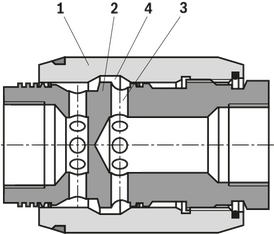

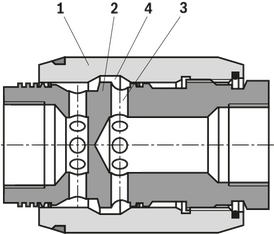

Throttling is realized in both directions of flow. The hydraulic fluid is directed to the throttling point (4) via lateral bores (3). It is formed between the housing (2) and the adjustable sleeve (1). By rotating the sleeve (1), the cross-section of the throttling point (4) can be steplessly adjusted.

The valves type MG are pressure- and viscosity-dependent throttle valves.

Throttling is realized in both directions of flow. The hydraulic fluid is directed to the throttling point (4) via lateral bores (3). It is formed between the housing (2) and the adjustable sleeve (1). By rotating the sleeve (1), the cross-section of the throttling point (4) can be steplessly adjusted.

01 | 02 | 03 | 04 | 05 | 06 | 07 | |

MG | G | 1X | / | * |

01 | Throttle valve | MG |

02 | Size 6 | 6 |

Size 8 | 8 | |

Size 10 | 10 | |

Size 15 | 15 | |

Size 20 | 20 | |

Size 25 | 25 | |

Size 30 | 30 | |

03 | For threaded connection | G |

04 | Component series 10 ... 19 (10 ... 19: unchanged installation and connection dimensions) | 1X |

Corrosion resistance (outside) | ||

05 | None (valve housing primed) | no code |

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) | J3 | |

Improved corrosion protection (720 h salt spray test according to EN ISO 9227) | J5 | |

Seal material (observe compatibility of seals with hydraulic fluid used, see "Technical data") | ||

06 | NBR seals | no code |

FKM seals | V | |

07 | Further details in the plain text | * |

Notice:

For valve types for use in potentially explosive areas, refer to data sheet 07011.

01 | 02 | 03 | 04 | 05 | 06 | 07 | |

MG | G | 1X | / | * |

01 | Throttle valve | MG |

02 | Size 6 | 6 |

Size 8 | 8 | |

Size 10 | 10 | |

Size 15 | 15 | |

Size 20 | 20 | |

Size 25 | 25 | |

Size 30 | 30 | |

03 | For threaded connection | G |

04 | Component series 10 ... 19 (10 ... 19: unchanged installation and connection dimensions) | 1X |

Corrosion resistance (outside) | ||

05 | None (valve housing primed) | no code |

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) | J3 | |

Improved corrosion protection (720 h salt spray test according to EN ISO 9227) | J5 | |

Seal material (observe compatibility of seals with hydraulic fluid used, see "Technical data") | ||

06 | NBR seals | no code |

FKM seals | V | |

07 | Further details in the plain text | * |

Notice:

For valve types for use in potentially explosive areas, refer to data sheet 07011.

Size | 6 | 8 | 10 | 15 | 20 | 25 | 30 | ||

Weight | kg | 0.3 | 0.4 | 0.7 | 1.1 | 1.9 | 3.2 | 4.1 | |

Installation position | any | ||||||||

Ambient temperature | NBR seals | °C | -30 … +80 | ||||||

FKM seals | °C | -20 … +80 | |||||||

Size | 6 | 8 | 10 | 15 | 20 | 25 | 30 | ||

Maximum operating pressure | bar | 315 | |||||||

Maximum flow | See characteristic curves | ||||||||

Leakage flow 1) | Standard | l/min | 0.8 | 1 | 2 | 3 | 4 | 5.5 | |

Version "J3" and "J5" | l/min | 1.6 | 2.5 | 3.2 | 3.5 | 7 | 7.7 | ||

Hydraulic fluid | see table "Hydraulic fluid" | ||||||||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 | ||||||

FKM seals | °C | -20 … +80 | |||||||

Viscosity range | mm²/s | 10 … 800 | |||||||

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 2) | Class 20/18/15 | ||||||||

Load cycles | million | 10 | 2 | ||||||

| 1) | If valve is completely closed |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable 1) | Insoluble in water | HETG | FKM | ISO 15380 | 90221 |

HEES | FKM | ||||

Soluble in water | HEPG | FKM | ISO 15380 | ||

Flame-resistant | Water-free | HFDU (glycol base) | FKM | ISO 12922 | 90222 |

HFDU (ester base) 1) | FKM | ||||

HFDR | FKM | ||||

Containing water 1) | HFC (Fuchs Hydrotherm 46M, Fuchs Renosafe 500, Petrofer Ultra Safe 620, Houghton Houghto Safe 620, Union Carbide HP5046) | NBR | ISO 12922 | 90223 | |

Important information on hydraulic fluids:

| |||||

| 1) | Not recommended for corrosion-protected version "J3" and "J5" (contains zinc) |

Size | 6 | 8 | 10 | 15 | 20 | 25 | 30 | ||

Weight | kg | 0.3 | 0.4 | 0.7 | 1.1 | 1.9 | 3.2 | 4.1 | |

Installation position | any | ||||||||

Ambient temperature | NBR seals | °C | -30 … +80 | ||||||

FKM seals | °C | -20 … +80 | |||||||

Size | 6 | 8 | 10 | 15 | 20 | 25 | 30 | ||

Maximum operating pressure | bar | 315 | |||||||

Maximum flow | See characteristic curves | ||||||||

Leakage flow 1) | Standard | l/min | 0.8 | 1 | 2 | 3 | 4 | 5.5 | |

Version "J3" and "J5" | l/min | 1.6 | 2.5 | 3.2 | 3.5 | 7 | 7.7 | ||

Hydraulic fluid | see table "Hydraulic fluid" | ||||||||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 | ||||||

FKM seals | °C | -20 … +80 | |||||||

Viscosity range | mm²/s | 10 … 800 | |||||||

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 2) | Class 20/18/15 | ||||||||

Load cycles | million | 10 | 2 | ||||||

| 1) | If valve is completely closed |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable 1) | Insoluble in water | HETG | FKM | ISO 15380 | 90221 |

HEES | FKM | ||||

Soluble in water | HEPG | FKM | ISO 15380 | ||

Flame-resistant | Water-free | HFDU (glycol base) | FKM | ISO 12922 | 90222 |

HFDU (ester base) 1) | FKM | ||||

HFDR | FKM | ||||

Containing water 1) | HFC (Fuchs Hydrotherm 46M, Fuchs Renosafe 500, Petrofer Ultra Safe 620, Houghton Houghto Safe 620, Union Carbide HP5046) | NBR | ISO 12922 | 90223 | |

Important information on hydraulic fluids:

| |||||

| 1) | Not recommended for corrosion-protected version "J3" and "J5" (contains zinc) |

Dimensions in mm

1 | Valve marking on key face |

NG | D1 | ØD2 | L | SW1 | SW2 | T |

mm | mm | mm | mm | mm | ||

| 6 | G1/4 | 34 | 65 | 22 | 32 | 12 |

| 8 | G3/8 | 38 | 65 | 24 | 36 | 12 |

| 10 | G1/2 | 48 | 80 | 30 | 46 | 14 |

| 15 | G3/4 | 58 | 100 | 41 | 55 | 16 |

| 20 | G1 | 72 | 110 | 46 | 70 | 18 |

| 25 | G1 1/4 | 87 | 130 | 55 | 85 | 20 |

| 30 | G1 1/2 | 93 | 150 | 60 | 90 | 22 |

Dimensions in mm

1 | Valve marking on key face |

NG | D1 | ØD2 | L | SW1 | SW2 | T |

mm | mm | mm | mm | mm | ||

| 6 | G1/4 | 34 | 65 | 22 | 32 | 12 |

| 8 | G3/8 | 38 | 65 | 24 | 36 | 12 |

| 10 | G1/2 | 48 | 80 | 30 | 46 | 14 |

| 15 | G3/4 | 58 | 100 | 41 | 55 | 16 |

| 20 | G1 | 72 | 110 | 46 | 70 | 18 |

| 25 | G1 1/4 | 87 | 130 | 55 | 85 | 20 |

| 30 | G1 1/2 | 93 | 150 | 60 | 90 | 22 |