| Availability: | |

|---|---|

| Quantity: | |

LC 25 A20E7X/

Rexroth

R900910270

Valve poppet with or without damping nose

2 area ratios

6 different cracking pressures

Valve poppet with or without damping nose

2 area ratios

6 different cracking pressures

2-way cartridge valves are elements that have been designed for a compact block design. The power section with connections A and B is installed into the control block in a receiving hole standardized according to ISO 7368 and closed with a cover. In most cases, the cover is also the connection from the control side of the power section to the pilot control valves.

By control with respective pilot control valves, the power section can be applied for pressure, directional and throttle functions or a combination of these functions. Particularly efficient solutions are realized by adjustment of the size to various flows of the individual ways of an actuator. The application of power sections of elements for multiple functions is very cost-effective.

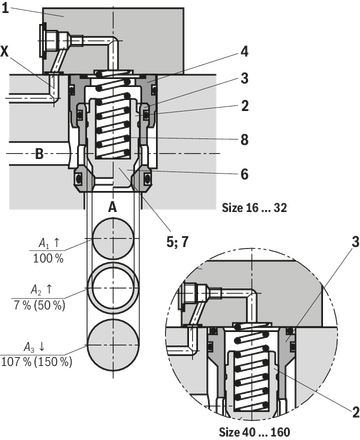

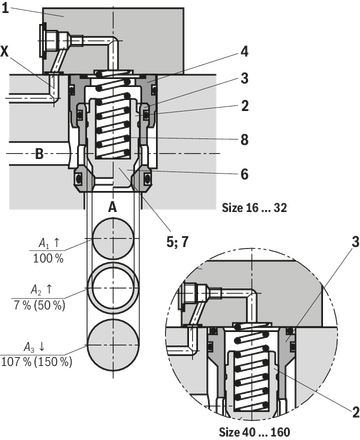

2-way cartridge valves generally consist of control cover (1) and installation kit (2). The control cover contains the control bores and optionally a stroke limitation function, a hydraulically controlled directional seat valve or a shuttle valve according to the required overall function. Additionally, electrically operated directional spool or seat valves can be installed at a control cover. The installation kit consists of a bushing (3), ring (4) (only up to NG32), valve poppet (5), optionally with damping nose (6) or without damping nose (7) as well as closing spring (8).

The function of 2-way cartridge valves is pressure-dependent. This way, three crucial pressurized areas are realized for the function. A1, A2, A3. The area at valve seat A1 is observed as 100 %. Depending on the version, the annulus area A2 realized by grading is 7 % or 50 % of area A1. The area ratio A1 : A2 is respectively either 14.3 : 1 or 2 : 1. The area A3 is identical to the sum of areas A1 + A2. Due to the different area ratios A1 : A2 and the resulting different annulus areas (A2), the area A3 is one time 107 % and another time 150 % of the area A1 at the seat, which is observed as 100 %.

In general, the following applies:

The areas A1 and A2 are effective in opening direction. The area A3 and the spring are effective in closing direction. The direction of action of the resulting force from the opening and closing forces determines the spool position of the 2-way cartridge valve.

The 2-way cartridge valves can be passed from A to B or from B to A. Pressurization of area A3 by pilot oil discharge from channel B or external pilot oil supply, channel A is blocked without leakage.

2-way cartridge valves are elements that have been designed for a compact block design. The power section with connections A and B is installed into the control block in a receiving hole standardized according to ISO 7368 and closed with a cover. In most cases, the cover is also the connection from the control side of the power section to the pilot control valves.

By control with respective pilot control valves, the power section can be applied for pressure, directional and throttle functions or a combination of these functions. Particularly efficient solutions are realized by adjustment of the size to various flows of the individual ways of an actuator. The application of power sections of elements for multiple functions is very cost-effective.

2-way cartridge valves generally consist of control cover (1) and installation kit (2). The control cover contains the control bores and optionally a stroke limitation function, a hydraulically controlled directional seat valve or a shuttle valve according to the required overall function. Additionally, electrically operated directional spool or seat valves can be installed at a control cover. The installation kit consists of a bushing (3), ring (4) (only up to NG32), valve poppet (5), optionally with damping nose (6) or without damping nose (7) as well as closing spring (8).

The function of 2-way cartridge valves is pressure-dependent. This way, three crucial pressurized areas are realized for the function. A1, A2, A3. The area at valve seat A1 is observed as 100 %. Depending on the version, the annulus area A2 realized by grading is 7 % or 50 % of area A1. The area ratio A1 : A2 is respectively either 14.3 : 1 or 2 : 1. The area A3 is identical to the sum of areas A1 + A2. Due to the different area ratios A1 : A2 and the resulting different annulus areas (A2), the area A3 is one time 107 % and another time 150 % of the area A1 at the seat, which is observed as 100 %.

In general, the following applies:

The areas A1 and A2 are effective in opening direction. The area A3 and the spring are effective in closing direction. The direction of action of the resulting force from the opening and closing forces determines the spool position of the 2-way cartridge valve.

The 2-way cartridge valves can be passed from A to B or from B to A. Pressurization of area A3 by pilot oil discharge from channel B or external pilot oil supply, channel A is blocked without leakage.

01 | 02 | 03 | 04 | 05 | 06 | 07 | |

LC | / |

Type | ||

01 | Cartridge valve | LC |

Size | ||

02 | Size 16 | 16 |

Size 25 | 25 | |

Size 32 | 32 | |

Size 40 | 40 | |

Size 50 | 50 | |

Size 63 | 63 | |

Size 80 | 80 | |

Size 100 | 100 | |

Size 125 | 125 | |

Size 160 | 160 | |

Spool design 1) | ||

03 | A1 : A2 = 2 : 1 (A2 = 50 %) | A |

A1 : A2 = 14.3 : 1 (A2 = 7 %) | B | |

Cracking pressure | ||

04 | 0 bar (without spring) | 00 |

approx. 0.5 bar | 05 | |

approx. 1 bar | 10 | |

approx. 2 bar | 20 | |

approx. 3 bar (NG125 only) | 30 | |

approx. 4 bar (not NG125) | 40 | |

Damping | ||

05 | Valve poppet without damping nose | E |

Valve poppet with damping nose | D | |

Component series | ||

06 | Component series 70 ... 79 (70 ... 79: unchanged installation and connection dimensions) 2) | 7X |

Component series 60 … 69 (60 … 69: unchanged installation and connection dimensions) 3) | 6X | |

Component series 20 … 29 (20 … 29: unchanged installation and connection dimensions) 4) | 2X | |

Seal material | ||

07 | NBR seals | no code |

FKM seals | V | |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | ||

| 1) | See "Product description" |

| 2) | Size 16 ... 63 |

| 3) | Size 80 ... 100 |

| 4) | Size 125 ... 160 |

01 | 02 | 03 | 04 | 05 | 06 | 07 | |

LC | / |

Type | ||

01 | Cartridge valve | LC |

Size | ||

02 | Size 16 | 16 |

Size 25 | 25 | |

Size 32 | 32 | |

Size 40 | 40 | |

Size 50 | 50 | |

Size 63 | 63 | |

Size 80 | 80 | |

Size 100 | 100 | |

Size 125 | 125 | |

Size 160 | 160 | |

Spool design 1) | ||

03 | A1 : A2 = 2 : 1 (A2 = 50 %) | A |

A1 : A2 = 14.3 : 1 (A2 = 7 %) | B | |

Cracking pressure | ||

04 | 0 bar (without spring) | 00 |

approx. 0.5 bar | 05 | |

approx. 1 bar | 10 | |

approx. 2 bar | 20 | |

approx. 3 bar (NG125 only) | 30 | |

approx. 4 bar (not NG125) | 40 | |

Damping | ||

05 | Valve poppet without damping nose | E |

Valve poppet with damping nose | D | |

Component series | ||

06 | Component series 70 ... 79 (70 ... 79: unchanged installation and connection dimensions) 2) | 7X |

Component series 60 … 69 (60 … 69: unchanged installation and connection dimensions) 3) | 6X | |

Component series 20 … 29 (20 … 29: unchanged installation and connection dimensions) 4) | 2X | |

Seal material | ||

07 | NBR seals | no code |

FKM seals | V | |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | ||

| 1) | See "Product description" |

| 2) | Size 16 ... 63 |

| 3) | Size 80 ... 100 |

| 4) | Size 125 ... 160 |

Size | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | ||

Weight | kg | 0.25 | 0.5 | 1.1 | 1.9 | 3.9 | 7.2 | 13 | 27 | 44 | 75 | |

Ambient temperature range | NBR seals | °C | -30 … +60 | |||||||||

FKM seals | °C | -20 … +60 | ||||||||||

MTTFD values according to EN ISO 13849 1) | Years | 150 | ||||||||||

| 1) | For further details, see data sheet 08012 |

Size | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | ||

Maximum operating pressure 1) | Anschluss A | bar | 315 350 420 | |||||||||

Port B | bar | 315 350 420 | ||||||||||

Maximum flow 2) | l/min | 420 | 900 | 1500 | 2500 | 3500 | 6500 | 8500 | 13000 | 18000 | 25000 | |

Hydraulic fluid | see table "Hydraulic fluid" | |||||||||||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 | |||||||||

FKM seals | °C | -20 … +80 | ||||||||||

Viscosity range | mm²/s | 2.8 … 500 | ||||||||||

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 3) | Class 20/18/15 | |||||||||||

| 1) | dependent on the attached directional valve |

| 2) | NG-dependent; see characteristic curves |

| 3) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP, HLPD, HVLP, HVLPD | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable 1) | Insoluble in water | HETG | NBR, FKM | ISO 15380 | 90221 |

HEES | FKM | ||||

Soluble in water | HEPG | FKM | ISO 15380 | ||

Flame-resistant | Water-free | HFDU (glycol base) | FKM | ISO 12922 | 90222 |

HFDU (ester base) 1) | FKM | ||||

Containing water 1) | HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) | NBR | ISO 12922 | 90223 | |

Important information on hydraulic fluids:

| |||||

| 1) | Not recommended for corrosion-protected version "J3" (contains zinc) |

Surface in cm2 | Version | Size | |||||||||

16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | ||

A1 | LC..A.. | 1,89 | 4,26 | 6,79 | 11,1 | 19,63 | 30,02 | 37,9 | 63,6 | 95 | 160,6 |

LC..B.. | 2,66 | 5,73 | 9,51 | 15,55 | 26,42 | 41,28 | 52,8 | 89,1 | 133,7 | 224,8 | |

A2 | LC..A.. | 0,95 | 1,89 | 3,39 | 5,52 | 8,64 | 14,0 | 18,84 | 31,4 | 48 | 79,9 |

LC..B.. | 0,18 | 0,43 | 0,67 | 1,07 | 1,85 | 2,90 | 3,94 | 5,9 | 9,3 | 15,7 | |

A3 | LC..A.. | 2,84 | 6,16 | 10,18 | 16,62 | 28,27 | 44,2 | 56,74 | 95 | 143 | 240,5 |

LC..B.. | 2,84 | 6,16 | 10,18 | 16,62 | 28,27 | 44,2 | 56,74 | 95 | 143 | 240,5 | |

Version | Size | |||||||||||

16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | |||

Stroke | cm | LC..E.. | 0,9 | 1,17 | 1,4 | 1,7 | 2,1 | 2,3 | 2,4 | 3,0 | 3,8 | 5,0 |

LC..D.. | 0,9 | 1,17 | 1,4 | 1,9 | 2,3 | 2,8 | 3,0 | 3,8 | 4,8 | 6,5 | ||

Pilot volume | cm3 | LC..E.. | 2,56 | 7,21 | 14,3 | 28,3 | 59,4 | 102 | 136 | 285 | 544 | 1203 |

LC..D.. | 2,56 | 7,21 | 14,3 | 31,6 | 65,0 | 124 | 170 | 361 | 687 | 1563 | ||

Theoretical pilot flow 1) | l/min | LC..E.. | 15,4 | 43,3 | 86 | 170 | 356 | 612 | 816 | 1710 | 3264 | 7218 |

LC..D.. | 15,4 | 43,3 | 86 | 190 | 390 | 744 | 1020 | 2166 | 4122 | 9378 | ||

| 1) | Theoretical pilot flow for realization of a switching time of 10 ms |

Notice:

Spools with damping nose are mainly used in applications with stroke limitation and spool position monitoring. Due to the better flow values, we recommend the spool without damping nose by default.

Version | Size | ||||||||||

16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | ||

Direction of flow A to B | LC..A 00.. | 0,02 | 0,025 | 0,05 | 0,05 | 0,05 | 0,07 | 0,07 | 0,1 | 0,15 | 0,15 |

LC..A 05.. | 0,35 | 0,35 | 0,36 | 0,35 | 0,37 | 0,31 | 0,44 | 0,43 | 0,43 | 0,45 | |

LC..A 10.. | 0,70 | 0,68 | 0,72 | 0,71 | 0,67 | 0,64 | 0,88 | 0,88 | 0,88 | – | |

LC..A 20.. | 2,03 | 2,18 | 2,12 | 2,02 | 2,01 | 2,0 | 1,75 | 1,75 | 1,76 | 1,94 | |

LC..A 30.. | – | – | – | – | – | – | – | – | 2,05 | – | |

LC..A 40.. | 3,50 | 3,90 | 3,80 | 4 | 4,11 | 3,8 | 3,13 | 3,04 | – | 4,42 | |

LC..B 00.. | 0,014 | 0,02 | 0,035 | 0,035 | 0,035 | 0,05 | 0,05 | 0,07 | 0,1 | 0,1 | |

LC..B 05.. | 0,25 | 0,26 | 0,26 | 0,25 | 0,28 | 0,23 | 0,31 | 0,31 | 0,31 | 0,32 | |

LC..B 10.. | 0,49 | 0,50 | 0,51 | 0,51 | 0,48 | 0,47 | 0,63 | 0,63 | 0,62 | – | |

LC..B 20.. | 1,44 | 1,62 | 1,52 | 1,44 | 1,5 | 1,5 | 1,26 | 1,25 | 1,25 | 1,4 | |

LC..B 30.. | – | – | – | – | – | – | – | – | 1,45 | – | |

LC..B 40.. | 2,48 | 2,90 | 2,70 | 2,86 | 3,05 | 2,8 | 2,25 | 2,17 | – | 3,35 | |

Direction of flow B to A | LC..A 00.. | 0,04 | 0,05 | 0,1 | 0,1 | 0,1 | 0,14 | 0,14 | 0,2 | 0,30 | 0,33 |

LC..A 05.. | 0,69 | 0,78 | 0,72 | 0,7 | 0,84 | 0,68 | 0,88 | 0,88 | 0,86 | 0,91 | |

LC..A 10.. | 1,38 | 1,53 | 1,42 | 1,43 | 1,47 | 1,37 | 1,77 | 1,78 | 1,73 | – | |

LC..A 20.. | 4,05 | 4,91 | 4,25 | 4,06 | 4,57 | 4,33 | 3,53 | 3,54 | 3,50 | 3,9 | |

LC..A 30.. | – | – | – | – | – | – | – | – | 4,0 | – | |

LC..A 40.. | 6,96 | 8,74 | 7,6 | 8,05 | 9,34 | 8,15 | 6,3 | 6,2 | – | 8,76 | |

LC..B 00.. | 0,24 | 0,25 | 0,5 | 0,5 | 0,5 | 0,8 | 0,7 | 1,0 | 1,5 | 1,5 | |

LC..B 05.. | 3,69 | 3,40 | 3,64 | 3,64 | 3,95 | 3,27 | 4,2 | 4,6 | 4,4 | 4,6 | |

LC..B 10.. | 7,43 | 6,69 | 7,24 | 7,37 | 6,88 | 6,62 | 8,4 | 9,4 | 8,9 | – | |

LC..B 20.. | 21,3 | 21,5 | 21,6 | 20,9 | 21,4 | 20,9 | 16,9 | 18,7 | 17,9 | 20 | |

LC..B 30.. | – | – | – | – | – | – | – | – | 20,7 | – | |

LC..B 40.. | 36,6 | 38,3 | 38,6 | 41,5 | 43,6 | 39,4 | 30,2 | 32,5 | – | 44,7 | |

Size | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | ||

Weight | kg | 0.25 | 0.5 | 1.1 | 1.9 | 3.9 | 7.2 | 13 | 27 | 44 | 75 | |

Ambient temperature range | NBR seals | °C | -30 … +60 | |||||||||

FKM seals | °C | -20 … +60 | ||||||||||

MTTFD values according to EN ISO 13849 1) | Years | 150 | ||||||||||

| 1) | For further details, see data sheet 08012 |

Size | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | ||

Maximum operating pressure 1) | Anschluss A | bar | 315 350 420 | |||||||||

Port B | bar | 315 350 420 | ||||||||||

Maximum flow 2) | l/min | 420 | 900 | 1500 | 2500 | 3500 | 6500 | 8500 | 13000 | 18000 | 25000 | |

Hydraulic fluid | see table "Hydraulic fluid" | |||||||||||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 | |||||||||

FKM seals | °C | -20 … +80 | ||||||||||

Viscosity range | mm²/s | 2.8 … 500 | ||||||||||

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 3) | Class 20/18/15 | |||||||||||

| 1) | dependent on the attached directional valve |

| 2) | NG-dependent; see characteristic curves |

| 3) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP, HLPD, HVLP, HVLPD | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable 1) | Insoluble in water | HETG | NBR, FKM | ISO 15380 | 90221 |

HEES | FKM | ||||

Soluble in water | HEPG | FKM | ISO 15380 | ||

Flame-resistant | Water-free | HFDU (glycol base) | FKM | ISO 12922 | 90222 |

HFDU (ester base) 1) | FKM | ||||

Containing water 1) | HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) | NBR | ISO 12922 | 90223 | |

Important information on hydraulic fluids:

| |||||

| 1) | Not recommended for corrosion-protected version "J3" (contains zinc) |

Surface in cm2 | Version | Size | |||||||||

16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | ||

A1 | LC..A.. | 1,89 | 4,26 | 6,79 | 11,1 | 19,63 | 30,02 | 37,9 | 63,6 | 95 | 160,6 |

LC..B.. | 2,66 | 5,73 | 9,51 | 15,55 | 26,42 | 41,28 | 52,8 | 89,1 | 133,7 | 224,8 | |

A2 | LC..A.. | 0,95 | 1,89 | 3,39 | 5,52 | 8,64 | 14,0 | 18,84 | 31,4 | 48 | 79,9 |

LC..B.. | 0,18 | 0,43 | 0,67 | 1,07 | 1,85 | 2,90 | 3,94 | 5,9 | 9,3 | 15,7 | |

A3 | LC..A.. | 2,84 | 6,16 | 10,18 | 16,62 | 28,27 | 44,2 | 56,74 | 95 | 143 | 240,5 |

LC..B.. | 2,84 | 6,16 | 10,18 | 16,62 | 28,27 | 44,2 | 56,74 | 95 | 143 | 240,5 | |

Version | Size | |||||||||||

16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | |||

Stroke | cm | LC..E.. | 0,9 | 1,17 | 1,4 | 1,7 | 2,1 | 2,3 | 2,4 | 3,0 | 3,8 | 5,0 |

LC..D.. | 0,9 | 1,17 | 1,4 | 1,9 | 2,3 | 2,8 | 3,0 | 3,8 | 4,8 | 6,5 | ||

Pilot volume | cm3 | LC..E.. | 2,56 | 7,21 | 14,3 | 28,3 | 59,4 | 102 | 136 | 285 | 544 | 1203 |

LC..D.. | 2,56 | 7,21 | 14,3 | 31,6 | 65,0 | 124 | 170 | 361 | 687 | 1563 | ||

Theoretical pilot flow 1) | l/min | LC..E.. | 15,4 | 43,3 | 86 | 170 | 356 | 612 | 816 | 1710 | 3264 | 7218 |

LC..D.. | 15,4 | 43,3 | 86 | 190 | 390 | 744 | 1020 | 2166 | 4122 | 9378 | ||

| 1) | Theoretical pilot flow for realization of a switching time of 10 ms |

Notice:

Spools with damping nose are mainly used in applications with stroke limitation and spool position monitoring. Due to the better flow values, we recommend the spool without damping nose by default.

Version | Size | ||||||||||

16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | ||

Direction of flow A to B | LC..A 00.. | 0,02 | 0,025 | 0,05 | 0,05 | 0,05 | 0,07 | 0,07 | 0,1 | 0,15 | 0,15 |

LC..A 05.. | 0,35 | 0,35 | 0,36 | 0,35 | 0,37 | 0,31 | 0,44 | 0,43 | 0,43 | 0,45 | |

LC..A 10.. | 0,70 | 0,68 | 0,72 | 0,71 | 0,67 | 0,64 | 0,88 | 0,88 | 0,88 | – | |

LC..A 20.. | 2,03 | 2,18 | 2,12 | 2,02 | 2,01 | 2,0 | 1,75 | 1,75 | 1,76 | 1,94 | |

LC..A 30.. | – | – | – | – | – | – | – | – | 2,05 | – | |

LC..A 40.. | 3,50 | 3,90 | 3,80 | 4 | 4,11 | 3,8 | 3,13 | 3,04 | – | 4,42 | |

LC..B 00.. | 0,014 | 0,02 | 0,035 | 0,035 | 0,035 | 0,05 | 0,05 | 0,07 | 0,1 | 0,1 | |

LC..B 05.. | 0,25 | 0,26 | 0,26 | 0,25 | 0,28 | 0,23 | 0,31 | 0,31 | 0,31 | 0,32 | |

LC..B 10.. | 0,49 | 0,50 | 0,51 | 0,51 | 0,48 | 0,47 | 0,63 | 0,63 | 0,62 | – | |

LC..B 20.. | 1,44 | 1,62 | 1,52 | 1,44 | 1,5 | 1,5 | 1,26 | 1,25 | 1,25 | 1,4 | |

LC..B 30.. | – | – | – | – | – | – | – | – | 1,45 | – | |

LC..B 40.. | 2,48 | 2,90 | 2,70 | 2,86 | 3,05 | 2,8 | 2,25 | 2,17 | – | 3,35 | |

Direction of flow B to A | LC..A 00.. | 0,04 | 0,05 | 0,1 | 0,1 | 0,1 | 0,14 | 0,14 | 0,2 | 0,30 | 0,33 |

LC..A 05.. | 0,69 | 0,78 | 0,72 | 0,7 | 0,84 | 0,68 | 0,88 | 0,88 | 0,86 | 0,91 | |

LC..A 10.. | 1,38 | 1,53 | 1,42 | 1,43 | 1,47 | 1,37 | 1,77 | 1,78 | 1,73 | – | |

LC..A 20.. | 4,05 | 4,91 | 4,25 | 4,06 | 4,57 | 4,33 | 3,53 | 3,54 | 3,50 | 3,9 | |

LC..A 30.. | – | – | – | – | – | – | – | – | 4,0 | – | |

LC..A 40.. | 6,96 | 8,74 | 7,6 | 8,05 | 9,34 | 8,15 | 6,3 | 6,2 | – | 8,76 | |

LC..B 00.. | 0,24 | 0,25 | 0,5 | 0,5 | 0,5 | 0,8 | 0,7 | 1,0 | 1,5 | 1,5 | |

LC..B 05.. | 3,69 | 3,40 | 3,64 | 3,64 | 3,95 | 3,27 | 4,2 | 4,6 | 4,4 | 4,6 | |

LC..B 10.. | 7,43 | 6,69 | 7,24 | 7,37 | 6,88 | 6,62 | 8,4 | 9,4 | 8,9 | – | |

LC..B 20.. | 21,3 | 21,5 | 21,6 | 20,9 | 21,4 | 20,9 | 16,9 | 18,7 | 17,9 | 20 | |

LC..B 30.. | – | – | – | – | – | – | – | – | 20,7 | – | |

LC..B 40.. | 36,6 | 38,3 | 38,6 | 41,5 | 43,6 | 39,4 | 30,2 | 32,5 | – | 44,7 | |

Dimensions in mm

1 | Depth of fit |

2 | Port B may be positioned around the central axis of port A. However, it must be observed that the mounting bores and the control bores are not damaged. |

NG | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | |

ØD1H7 | mm | 32 | 45 | 60 | 75 | 90 | 120 | 145 | 180 | 225 | 300 |

ØD2 | mm | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 150 1) | 200 1) |

ØD3 | mm | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 |

(ØD3*) 2) | mm | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 250 |

ØD4H7 | 25 | 34 | 45 | 55 | 68 | 90 | 110 | 135 | 200 | 270 | |

H1 | mm | 42.5 | 57 | 68.5 | 84.5 | 97.5 | 127 | 170.5 | 205.5 | 255 | 368 |

H2 | mm | 56 | 72 | 85 | 105 | 122 | 155 | 205 | 245 | 300 | 425 |

mm | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.15 | + 0.15 | |

H3 | mm | 43 | 58 | 70 | 87 | 100 | 130 | 175 | 210 | 257 | 370 |

mm | + 0.2 | + 0.2 | + 0.2 | + 0.3 | + 0.3 | + 0.3 | + 0.4 | + 0.4 | + 0.5 | + 0.5 | |

H5 | mm | 11 | 12 | 13 | 15 | 17 | 20 | 25 | 29 | 31 | 45 |

H6 | mm | 2 | 2.5 | 2.5 | 3 | 3 | 4 | 5 | 5 | 7 | 8 |

mm | - | - | - | - | - | - | - | - | ± 0.5 | ± 0.5 | |

H7 | mm | 20 | 30 | 30 | 30 | 35 | 40 | 40 | 50 | 40 | 50 |

H8 | mm | 2 | 2.5 | 2.5 | 3 | 4 | 4 | 5 | 5 | 5.5 | 5.5 |

mm | - | - | - | - | - | - | - | - | ± 0.2 | ± 0.2 | |

W | mm | 0.05 | 0.05 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

Ro 1) | mm | 2 | 2 | 2 | 4 | 4 | 4 | 4 | 4 | 4 | 6.3 |

Ru 1) | mm | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 1) | Maximum dimension |

| 2) | Due to the use of a bore with ØD3*, port B protrudes over the upper limit of the area intended in ISO 7368. This is, however, possible due to the sealing concept and reduces the pressure loss during flow through the valve. Thus, we recommend a bore with ØD3*. |

Dimensions in mm

1 | Depth of fit |

2 | Port B may be positioned around the central axis of port A. However, it must be observed that the mounting bores and the control bores are not damaged. |

NG | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | |

ØD1H7 | mm | 32 | 45 | 60 | 75 | 90 | 120 | 145 | 180 | 225 | 300 |

ØD2 | mm | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 150 1) | 200 1) |

ØD3 | mm | 16 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 |

(ØD3*) 2) | mm | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 250 |

ØD4H7 | 25 | 34 | 45 | 55 | 68 | 90 | 110 | 135 | 200 | 270 | |

H1 | mm | 42.5 | 57 | 68.5 | 84.5 | 97.5 | 127 | 170.5 | 205.5 | 255 | 368 |

H2 | mm | 56 | 72 | 85 | 105 | 122 | 155 | 205 | 245 | 300 | 425 |

mm | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.1 | + 0.15 | + 0.15 | |

H3 | mm | 43 | 58 | 70 | 87 | 100 | 130 | 175 | 210 | 257 | 370 |

mm | + 0.2 | + 0.2 | + 0.2 | + 0.3 | + 0.3 | + 0.3 | + 0.4 | + 0.4 | + 0.5 | + 0.5 | |

H5 | mm | 11 | 12 | 13 | 15 | 17 | 20 | 25 | 29 | 31 | 45 |

H6 | mm | 2 | 2.5 | 2.5 | 3 | 3 | 4 | 5 | 5 | 7 | 8 |

mm | - | - | - | - | - | - | - | - | ± 0.5 | ± 0.5 | |

H7 | mm | 20 | 30 | 30 | 30 | 35 | 40 | 40 | 50 | 40 | 50 |

H8 | mm | 2 | 2.5 | 2.5 | 3 | 4 | 4 | 5 | 5 | 5.5 | 5.5 |

mm | - | - | - | - | - | - | - | - | ± 0.2 | ± 0.2 | |

W | mm | 0.05 | 0.05 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

Ro 1) | mm | 2 | 2 | 2 | 4 | 4 | 4 | 4 | 4 | 4 | 6.3 |

Ru 1) | mm | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 1) | Maximum dimension |

| 2) | Due to the use of a bore with ØD3*, port B protrudes over the upper limit of the area intended in ISO 7368. This is, however, possible due to the sealing concept and reduces the pressure loss during flow through the valve. Thus, we recommend a bore with ØD3*. |