| Availability: | |

|---|---|

| Quantity: | |

DR 20-5-5X/200YM

Rexroth

R900597233

For subplate mounting

Porting pattern according to ISO 5781

For threaded connection

As cartridge valve

4 optional adjustment types:

• Rotary knob

• Sleeve with hexagon and protective cap

• Lockable rotary knob with scale

• Rotary knob with scale

5 pressure ratings

Check valve, optional (subplate mounting only)

Corrosion-protected design

For subplate mounting

Porting pattern according to ISO 5781

For threaded connection

As cartridge valve

4 optional adjustment types:

• Rotary knob

• Sleeve with hexagon and protective cap

• Lockable rotary knob with scale

• Rotary knob with scale

5 pressure ratings

Check valve, optional (subplate mounting only)

Corrosion-protected design

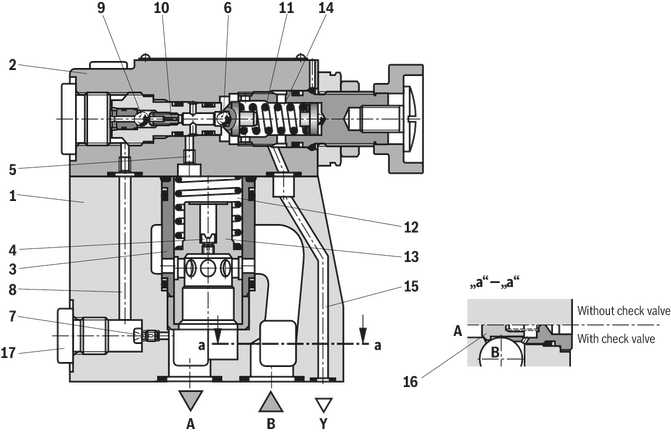

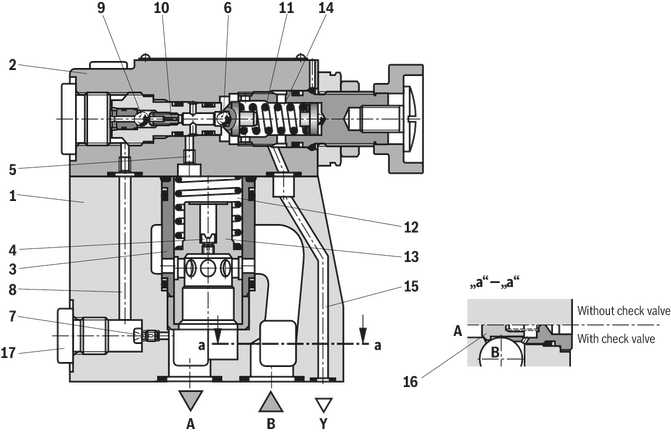

Pressure valves of type DR are pilot-operated pressure reducing valves controlled from the secondary circuit.

The pressure reducing valves basically consist of the main valve (1) with main spool insert (3) and pilot control valve (2) with adjustment type.

In the rest position the valves are open. Hydraulic fluid flows from channel B via the main spool insert (3) to channel A without restrictions. The pressure applied to channel A acts on the lower main spool side. Simultaneously, pressure is applied to the spring-loaded side of the main spool (3) via the nozzle (4) and to the ball (6) in the pilot control valve (2) via the channel (5). It also acts via the nozzle (7), control line (8), check valve (9) and nozzle (10) on the ball (6). Depending on the setting of the spring (11), a pressure builds up in front of the ball (6), in the channel (5) and in the spring chamber (12) holding the control spool (13) in the opened position. The hydraulic fluid in channel B can flow via the main spool insert (3) to channel A without restrictions until a pressure builds up in channel A which exceeds the value set at the spring (11) and opens the ball (6). The control spool (13) moves into closing direction.

The desired reduced pressure is achieved when there is a state of equilibrium between the pressure in channel A and the pressure set at the spring (11).

The pilot oil return from the spring chamber (14) is always realized externally via the control line (15) into the tank.

For the free flow back from channel A to channel B, a check valve (16) can optionally be installed.

A pressure gauge connection (17) allows for the control of the reduced pressure in channel A.

Pressure valves of type DR are pilot-operated pressure reducing valves controlled from the secondary circuit.

The pressure reducing valves basically consist of the main valve (1) with main spool insert (3) and pilot control valve (2) with adjustment type.

In the rest position the valves are open. Hydraulic fluid flows from channel B via the main spool insert (3) to channel A without restrictions. The pressure applied to channel A acts on the lower main spool side. Simultaneously, pressure is applied to the spring-loaded side of the main spool (3) via the nozzle (4) and to the ball (6) in the pilot control valve (2) via the channel (5). It also acts via the nozzle (7), control line (8), check valve (9) and nozzle (10) on the ball (6). Depending on the setting of the spring (11), a pressure builds up in front of the ball (6), in the channel (5) and in the spring chamber (12) holding the control spool (13) in the opened position. The hydraulic fluid in channel B can flow via the main spool insert (3) to channel A without restrictions until a pressure builds up in channel A which exceeds the value set at the spring (11) and opens the ball (6). The control spool (13) moves into closing direction.

The desired reduced pressure is achieved when there is a state of equilibrium between the pressure in channel A and the pressure set at the spring (11).

The pilot oil return from the spring chamber (14) is always realized externally via the control line (15) into the tank.

For the free flow back from channel A to channel B, a check valve (16) can optionally be installed.

A pressure gauge connection (17) allows for the control of the reduced pressure in channel A.

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | ||

DR | – | 5X | / | Y | * |

01 | Pressure reducing valve, pilot-operated | DR | ||

02 | Valve complete (subplate mounting or threaded connection) | no code | ||

Pilot control valve without main spool insert (cartridge valve; do not enter nominal size) | C | |||

Pilot control valve with main spool insert (cartridge valve) | C30 | |||

03 | Size | Subplate mounting "–" | Threaded connection "G" | |

10 | ✔ | ✔ (G1/2) | 10 | |

16 | – | ✔ (G3/4) | 15 1) | |

25 | ✔ | ✔ (G1) | 20 | |

25 | – | ✔ (G1 1/4) | 25 1) | |

32 | ✔ | ✔ (G1 1/2) | 30 | |

04 | As cartridge valve (version "C", without main spool insert) | no code | ||

As cartridge valve (version "C30", with main spool insert) | – | |||

For subplate mounting | – | |||

For threaded connection | G | |||

Adjustment type | ||||

05 | Rotary knob | 4 | ||

Sleeve with hexagon and protective cap ("J3" version without protective cap; always with maximum pressure adjustment) | 5 | |||

Lockable rotary knob with scale | 6 2) | |||

Rotary knob with scale | 7 | |||

06 | Component series 50 … 59 (50 … 59: unchanged installation and connection dimensions) | 5X | ||

07 | Set pressure up to 50 bar | 50 | ||

Set pressure up to 100 bar | 100 | |||

Set pressure up to 200 bar | 200 | |||

Set pressure up to 315 bar | 315 | |||

Set pressure up to 350 bar (only version "M") | 350 | |||

Pilot oil supply | ||||

08 | Internal pilot oil supply, external pilot oil return | Y | ||

09 | With check valve (only for subplate mounting) | no code 1) | ||

Without check valve | M | |||

Corrosion resistance | ||||

10 | None | no code | ||

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) (only version "5") | J3 | |||

Seal material (observe compatibility of seals with hydraulic fluid used, see "Technical data") | ||||

11 | NBR seals | no code | ||

FKM seals | V | |||

12 | Further details in the plain text | * | ||

| 1) | Not for version "J3" |

| 2) | H-Key with material no. R900008158 is included in the scope of delivery. |

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | ||

DR | – | 5X | / | Y | * |

01 | Pressure reducing valve, pilot-operated | DR | ||

02 | Valve complete (subplate mounting or threaded connection) | no code | ||

Pilot control valve without main spool insert (cartridge valve; do not enter nominal size) | C | |||

Pilot control valve with main spool insert (cartridge valve) | C30 | |||

03 | Size | Subplate mounting "–" | Threaded connection "G" | |

10 | ✔ | ✔ (G1/2) | 10 | |

16 | – | ✔ (G3/4) | 15 1) | |

25 | ✔ | ✔ (G1) | 20 | |

25 | – | ✔ (G1 1/4) | 25 1) | |

32 | ✔ | ✔ (G1 1/2) | 30 | |

04 | As cartridge valve (version "C", without main spool insert) | no code | ||

As cartridge valve (version "C30", with main spool insert) | – | |||

For subplate mounting | – | |||

For threaded connection | G | |||

Adjustment type | ||||

05 | Rotary knob | 4 | ||

Sleeve with hexagon and protective cap ("J3" version without protective cap; always with maximum pressure adjustment) | 5 | |||

Lockable rotary knob with scale | 6 2) | |||

Rotary knob with scale | 7 | |||

06 | Component series 50 … 59 (50 … 59: unchanged installation and connection dimensions) | 5X | ||

07 | Set pressure up to 50 bar | 50 | ||

Set pressure up to 100 bar | 100 | |||

Set pressure up to 200 bar | 200 | |||

Set pressure up to 315 bar | 315 | |||

Set pressure up to 350 bar (only version "M") | 350 | |||

Pilot oil supply | ||||

08 | Internal pilot oil supply, external pilot oil return | Y | ||

09 | With check valve (only for subplate mounting) | no code 1) | ||

Without check valve | M | |||

Corrosion resistance | ||||

10 | None | no code | ||

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) (only version "5") | J3 | |||

Seal material (observe compatibility of seals with hydraulic fluid used, see "Technical data") | ||||

11 | NBR seals | no code | ||

FKM seals | V | |||

12 | Further details in the plain text | * | ||

| 1) | Not for version "J3" |

| 2) | H-Key with material no. R900008158 is included in the scope of delivery. |

Size | 10 | 16 | 25 | 25 | 32 | |||

Version | "10" | "15" | "20" | "25" | "30" | |||

Weight | Subplate mounting | "DR . .‒" | kg | 3.4 | - | 5.3 | - | 8 |

Cartridge valve | "DRC" | kg | 1.2 | |||||

"DRC30" | kg | 1.5 | ||||||

Threaded connection | "DR . G" | kg | 5.3 | 5.2 | 5.1 | 5 | 4.8 | |

Installation position | any | |||||||

Ambient temperature range | NBR seals | °C | -30 … +50 | |||||

FKM seals | °C | -20 … +50 | ||||||

Size | 10 | 16 | 25 | 32 | |||

Maximum operating pressure 1) | Port B | bar | 350 | ||||

Maximum inlet pressure 1) | Port B | bar | 350 | ||||

Maximum outlet pressure 1) | bar | 350 | |||||

Operating pressure range 1) | Anschluss A | bar | 10 … 350 | ||||

Maximum counter pressure 1) | Port Y | bar | 350 | ||||

Minimum set pressure | flow-dependent, see "characteristic curves" | ||||||

Maximum set pressure 1) | bar | 50 100 200 315 350 | |||||

Maximum flow | Subplate mounting | l/min | 150 | - | 300 | - | 400 |

Threaded connection | l/min | 150 | 300 | 400 | |||

Hydraulic fluid | see table "Hydraulic fluid" | ||||||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 | ||||

FKM seals | °C | -20 … +80 | |||||

Viscosity range | mm²/s | 10 … 800 | |||||

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 2) | Class 20/18/15 | ||||||

| 1) | 350 bar only possible at version "M" |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP, HLPD, HVLP, HVLPD | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable | Insoluble in water | HETG | NBR, FKM | ISO 15380 | 90221 |

HEES | FKM | ||||

Soluble in water | HEPG | FKM | ISO 15380 | ||

Flame-resistant | Water-free | HFDU (glycol base) | FKM | ISO 12922 | 90222 |

HFDU (ester base) | FKM | ||||

HFDR | FKM | ||||

Containing water | HFC (Fuchs: Hydrotherm 46M, Renosafe 500; | NBR | ISO 12922 | 90223 | |

Important information on hydraulic fluids:

| |||||

Size | 10 | 16 | 25 | 25 | 32 | |||

Version | "10" | "15" | "20" | "25" | "30" | |||

Weight | Subplate mounting | "DR . .‒" | kg | 3.4 | - | 5.3 | - | 8 |

Cartridge valve | "DRC" | kg | 1.2 | |||||

"DRC30" | kg | 1.5 | ||||||

Threaded connection | "DR . G" | kg | 5.3 | 5.2 | 5.1 | 5 | 4.8 | |

Installation position | any | |||||||

Ambient temperature range | NBR seals | °C | -30 … +50 | |||||

FKM seals | °C | -20 … +50 | ||||||

Size | 10 | 16 | 25 | 32 | |||

Maximum operating pressure 1) | Port B | bar | 350 | ||||

Maximum inlet pressure 1) | Port B | bar | 350 | ||||

Maximum outlet pressure 1) | bar | 350 | |||||

Operating pressure range 1) | Anschluss A | bar | 10 … 350 | ||||

Maximum counter pressure 1) | Port Y | bar | 350 | ||||

Minimum set pressure | flow-dependent, see "characteristic curves" | ||||||

Maximum set pressure 1) | bar | 50 100 200 315 350 | |||||

Maximum flow | Subplate mounting | l/min | 150 | - | 300 | - | 400 |

Threaded connection | l/min | 150 | 300 | 400 | |||

Hydraulic fluid | see table "Hydraulic fluid" | ||||||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 | ||||

FKM seals | °C | -20 … +80 | |||||

Viscosity range | mm²/s | 10 … 800 | |||||

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 2) | Class 20/18/15 | ||||||

| 1) | 350 bar only possible at version "M" |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet | |

Mineral oils | HL, HLP, HLPD, HVLP, HVLPD | NBR, FKM | DIN 51524 | 90220 | |

Bio-degradable | Insoluble in water | HETG | NBR, FKM | ISO 15380 | 90221 |

HEES | FKM | ||||

Soluble in water | HEPG | FKM | ISO 15380 | ||

Flame-resistant | Water-free | HFDU (glycol base) | FKM | ISO 12922 | 90222 |

HFDU (ester base) | FKM | ||||

HFDR | FKM | ||||

Containing water | HFC (Fuchs: Hydrotherm 46M, Renosafe 500; | NBR | ISO 12922 | 90223 | |

Important information on hydraulic fluids:

| |||||

Dimensions in mm

1 | Name plate |

2.1 | Y port for pilot oil return, external |

2.2 | Port Y optionally for external pilot oil return |

3 | Adjustment type "4" |

4 | Adjustment type "5" |

5 | Adjustment type "6" |

6 | Adjustment type "7" |

7 | Hexagon SW10 |

8 | Space required to remove the key |

9 | Valve mounting bores |

10 | Seal rings |

11 | Main spool insert |

12 | Seal ring |

13 | Seal ring |

14 | Seal ring |

15 | Support ring |

16 | Support ring |

Quantity | Hexagon socket head cap screws | Material number |

4 | ISO 4762 - M8 x 40 - 10.9-flZn/nc/480h/C (Friction coefficient μtotal = 0.09 … 0.14) Tightening torque MA = 31 Nm ±10 % | R913015798 |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Dimensions in mm

1 | Name plate |

2.1 | Y port for pilot oil return, external |

3 | Adjustment type "4" |

4 | Adjustment type "5" |

5 | Adjustment type "6" |

6 | Adjustment type "7" |

7 | Hexagon SW10 |

8 | Space required to remove the key |

9 | Valve mounting bores |

17 | Pressure gauge connection |

Version | D1 | ØD2 | T1 |

mm | mm | ||

| "10" | G1/2 | 34 | 14 |

| "15" | G3/4 | 42 | 16 |

| "20" | G1 | 47 | 18 |

| "25" | G1 1/4 | 58 | 20 |

| "30" | G1 1/2 | 65 | 22 |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Dimensions in mm

Required surface quality of the valve contact surface |

1 | Name plate |

2.1 | Y port for pilot oil return, external |

2.2 | Port Y optionally for external pilot oil return |

3 | Adjustment type "4" |

4 | Adjustment type "5" |

5 | Adjustment type "6" |

6 | Adjustment type "7" |

7 | Hexagon SW10 |

8 | Space required to remove the key |

9 | Valve mounting bores |

17 | Pressure gauge connection |

18 | Identical seal rings for ports A and B Identical seal rings for ports X and Y |

19 | Port X without function (blind bore) |

20 | Locking pin |

Version | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | B1 | B2 | B3 | B4 | B5 | H1 | H2 | H3 |

mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| "10" | 96 | 35.5 | 33 | 42.9 | 21.5 | - | 7.2 | 21.5 | 31.8 | 35.8 | 85 | 50 | 66.7 | 58.8 | 7.9 | 112 | 92 | 28 |

| "20" | 116 | 37.5 | 35.4 | 60.3 | 39.7 | - | 11.1 | 20.6 | 44.5 | 49.2 | 102 | 59.5 | 79.4 | 73 | 6.4 | 122 | 102 | 37 |

| "30" | 145 | 33 | 29.8 | 84.2 | 59.5 | 42.1 | 16.7 | 24.6 | 62.7 | 67.5 | 120 | 76 | 96.8 | 92.8 | 3.8 | 130 | 110 | 46 |

Version | Quantity | Hexagon socket head cap screws | Material number |

"10" | 4 | ISO 4762 - M10 x 50 - 10.9-flZn/nc/480h/C (Friction coefficient μtotal = 0.09 … 0.14) Tightening torque MA = 60 Nm | R913015580 |

"20" | 4 | ISO 4762 - M10 x 60 - 10.9-flZn/nc/480h/C (Friction coefficient μtotal = 0.09 … 0.14) Tightening torque MA = 60 Nm | R913014770 |

"30" | 6 | ISO 4762 - M10 x 70 - 10.9-flZn/nc/480h/C (Friction coefficient μtotal = 0.09 … 0.14) Tightening torque MA = 60 Nm | R913014772 |

Subplates (separate order) with porting pattern according to ISO 5783, see data sheet 45100.

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Dimensions in mm

1 | Notice: Bore Ø32 can cut into Ø45 at any position. However, it must be observed that the connection bores and valve mounting bore are not damaged. |

2 | Support ring and seal rings are to be inserted into this bore before assembly of the main spool! |

3 | Nozzle, separate order |

Dimensions in mm

1 | Name plate |

2.1 | Y port for pilot oil return, external |

2.2 | Port Y optionally for external pilot oil return |

3 | Adjustment type "4" |

4 | Adjustment type "5" |

5 | Adjustment type "6" |

6 | Adjustment type "7" |

7 | Hexagon SW10 |

8 | Space required to remove the key |

9 | Valve mounting bores |

10 | Seal rings |

11 | Main spool insert |

12 | Seal ring |

13 | Seal ring |

14 | Seal ring |

15 | Support ring |

16 | Support ring |

Quantity | Hexagon socket head cap screws | Material number |

4 | ISO 4762 - M8 x 40 - 10.9-flZn/nc/480h/C (Friction coefficient μtotal = 0.09 … 0.14) Tightening torque MA = 31 Nm ±10 % | R913015798 |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Dimensions in mm

1 | Name plate |

2.1 | Y port for pilot oil return, external |

3 | Adjustment type "4" |

4 | Adjustment type "5" |

5 | Adjustment type "6" |

6 | Adjustment type "7" |

7 | Hexagon SW10 |

8 | Space required to remove the key |

9 | Valve mounting bores |

17 | Pressure gauge connection |

Version | D1 | ØD2 | T1 |

mm | mm | ||

| "10" | G1/2 | 34 | 14 |

| "15" | G3/4 | 42 | 16 |

| "20" | G1 | 47 | 18 |

| "25" | G1 1/4 | 58 | 20 |

| "30" | G1 1/2 | 65 | 22 |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Dimensions in mm

Required surface quality of the valve contact surface |

1 | Name plate |

2.1 | Y port for pilot oil return, external |

2.2 | Port Y optionally for external pilot oil return |

3 | Adjustment type "4" |

4 | Adjustment type "5" |

5 | Adjustment type "6" |

6 | Adjustment type "7" |

7 | Hexagon SW10 |

8 | Space required to remove the key |

9 | Valve mounting bores |

17 | Pressure gauge connection |

18 | Identical seal rings for ports A and B Identical seal rings for ports X and Y |

19 | Port X without function (blind bore) |

20 | Locking pin |

Version | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | B1 | B2 | B3 | B4 | B5 | H1 | H2 | H3 |

mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| "10" | 96 | 35.5 | 33 | 42.9 | 21.5 | - | 7.2 | 21.5 | 31.8 | 35.8 | 85 | 50 | 66.7 | 58.8 | 7.9 | 112 | 92 | 28 |

| "20" | 116 | 37.5 | 35.4 | 60.3 | 39.7 | - | 11.1 | 20.6 | 44.5 | 49.2 | 102 | 59.5 | 79.4 | 73 | 6.4 | 122 | 102 | 37 |

| "30" | 145 | 33 | 29.8 | 84.2 | 59.5 | 42.1 | 16.7 | 24.6 | 62.7 | 67.5 | 120 | 76 | 96.8 | 92.8 | 3.8 | 130 | 110 | 46 |

Version | Quantity | Hexagon socket head cap screws | Material number |

"10" | 4 | ISO 4762 - M10 x 50 - 10.9-flZn/nc/480h/C (Friction coefficient μtotal = 0.09 … 0.14) Tightening torque MA = 60 Nm | R913015580 |

"20" | 4 | ISO 4762 - M10 x 60 - 10.9-flZn/nc/480h/C (Friction coefficient μtotal = 0.09 … 0.14) Tightening torque MA = 60 Nm | R913014770 |

"30" | 6 | ISO 4762 - M10 x 70 - 10.9-flZn/nc/480h/C (Friction coefficient μtotal = 0.09 … 0.14) Tightening torque MA = 60 Nm | R913014772 |

Subplates (separate order) with porting pattern according to ISO 5783, see data sheet 45100.

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Dimensions in mm

1 | Notice: Bore Ø32 can cut into Ø45 at any position. However, it must be observed that the connection bores and valve mounting bore are not damaged. |

2 | Support ring and seal rings are to be inserted into this bore before assembly of the main spool! |

3 | Nozzle, separate order |