| Availability: | |

|---|---|

| Quantity: | |

4WRZ 32 W8-520-7X/6EG24N9K4/D3M

Rexroth

R900704608

Pilot-operated 2-stage proportional directional valve without integrated electronics (OBE)

Control of the direction and magnitude of a flow

Operation by means of proportional solenoids with central thread and detachable coil

For subplate mounting: Porting pattern according to ISO 4401

Optional auxiliary operating device

Spring-centered control spool

Pilot-operated 2-stage proportional directional valve without integrated electronics (OBE)

Control of the direction and magnitude of a flow

Operation by means of proportional solenoids with central thread and detachable coil

For subplate mounting: Porting pattern according to ISO 4401

Optional auxiliary operating device

Spring-centered control spool

Valves of type 4WRZ(E)... are pilot-operated 4-directional valves that are actuated by means of proportional solenoids. Their function is to control the flow direction and size.

Valves of type 5WRZ(E)... are equipped with an additional port "R" (only NG52).

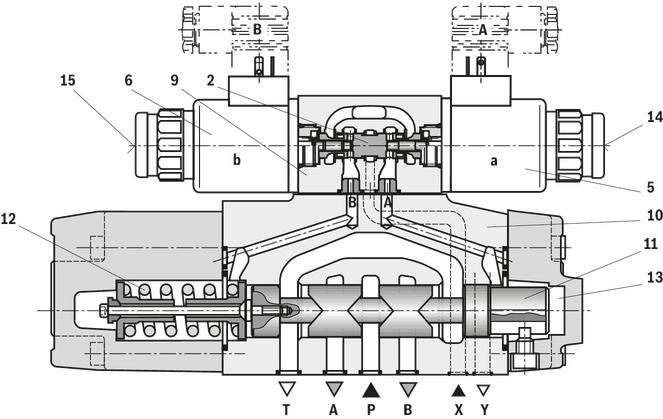

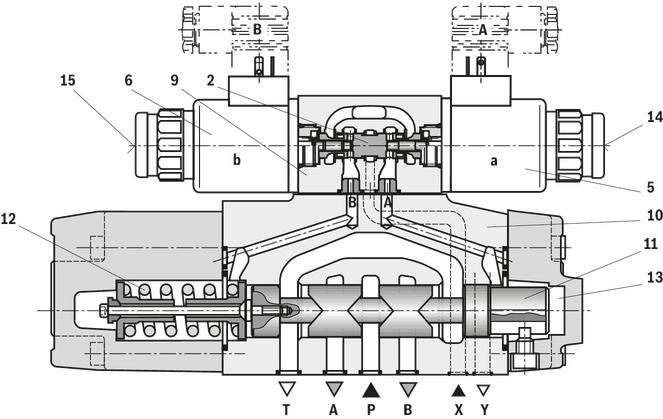

The valve basically consists of:

Pilot control valve (9) with proportional solenoids (5 and 6)

Main valve (10) with main control spool (11) and centering spring (12)

With de-energized solenoids (5, 6), the main control spool (11) is held in the central position by means of the centering spring (12)

The main control spool (11) is controlled by the pilot control valve (9); the main control spool is proportionally moved, e.g. by actuating solenoid "b" (6)

→ The control spool (2) is moved to the right, pilot oil enters the pressure chamber (13) via the pilot control valve (9) and deflects the main control spool (11) proportionally to the electric input signal

→ Connection from P to A and B to T via orifice-type cross-sections with progressive flow characteristics

Pilot oil supply to the pilot control valve internally via port P or externally via port X

Switching off the solenoid (6)

→ The control spool (2) and main control spool (11) are moved back into the central position

Depending on the spool position, flow occurs from P to A and B to T or P to B and A to T (R)

An optional manual override (14 and 15) can be used to move the control spool (2) without solenoid energization.

Accidental activation of the manual override may lead to uncontrolled machine movements!

Due to the design principle, internal leakage which may increase over the life cycle is inherent to the valves.

Valves of type 4WRZ(E)... are pilot-operated 4-directional valves that are actuated by means of proportional solenoids. Their function is to control the flow direction and size.

Valves of type 5WRZ(E)... are equipped with an additional port "R" (only NG52).

The valve basically consists of:

Pilot control valve (9) with proportional solenoids (5 and 6)

Main valve (10) with main control spool (11) and centering spring (12)

With de-energized solenoids (5, 6), the main control spool (11) is held in the central position by means of the centering spring (12)

The main control spool (11) is controlled by the pilot control valve (9); the main control spool is proportionally moved, e.g. by actuating solenoid "b" (6)

→ The control spool (2) is moved to the right, pilot oil enters the pressure chamber (13) via the pilot control valve (9) and deflects the main control spool (11) proportionally to the electric input signal

→ Connection from P to A and B to T via orifice-type cross-sections with progressive flow characteristics

Pilot oil supply to the pilot control valve internally via port P or externally via port X

Switching off the solenoid (6)

→ The control spool (2) and main control spool (11) are moved back into the central position

Depending on the spool position, flow occurs from P to A and B to T or P to B and A to T (R)

An optional manual override (14 and 15) can be used to move the control spool (2) without solenoid energization.

Accidental activation of the manual override may lead to uncontrolled machine movements!

Due to the design principle, internal leakage which may increase over the life cycle is inherent to the valves.

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | ||

4 | WRZ | ‒ | 7X | / | 6E | G24 | * |

01 | 4 main ports | 4 |

02 | Proportional directional valve with electro-hydraulic operation and external electronics | WRZ |

03 | Size 10 | 10 |

Size 16 | 16 | |

Size 25 | 25 | |

Size 32 | 32 | |

Size 52 | 52 | |

04 | Symbols; for the possible version, see "Symbols/Circuit diagrams" | E; E1-; E3-; W6-; W8-; W9-; EA; W6A |

Rated flow NG10 | ||

05 | 25 l/min | 25 |

50 l/min | 50 | |

90 l/min | 85 | |

Rated flow NG16 | ||

05 | 100 l/min | 100 |

125 l/min | 125 | |

150 l/min | 150 | |

180 l/min | 180 | |

Rated flow NG25 | ||

05 | 220 l/min | 220 |

325 l/min | 325 | |

Rated flow NG32 | ||

05 | 360 l/min | 360 |

520 l/min | 520 | |

Rated flow NG52 | ||

05 | 1000 l/min | 1000 |

06 | Component series 70 ... 79 (70 ... 79: unchanged installation and connection dimensions) | 7X |

07 | For subplate mounting | no code |

For flange connection (only NG 52) | F | |

08 | Pilot control valve NG6 | 6E |

09 | Supply voltage 24 V | G24 |

10 | Without manual override | no code |

With concealed manual override | N9 1) | |

11 | Without special type of protection | no code |

Sea water-resistant | J 2) | |

Pilot oil supply and return | ||

12 | External pilot oil supply, external pilot oil return | no code |

Internal pilot oil supply, external pilot oil return | E | |

Pilot oil supply internal, pilot oil return internal | ET | |

External pilot oil supply, internal pilot oil return | T | |

Electrical connection | ||

13 | Without mating connector, with connector according to DIN EN 175301-803, separate order | K43) |

Without mating connector, connector according to DIN EN 175201-804 | K31 3) | |

14 | Without pressure reducing valve | no code |

With pressure reducing valve ZDR 6 DP0-4X/40YM-W80 (fixedly set) | D3 | |

15 | NBR seals | M |

FKM seals | V | |

16 | Further details in the plain text | * |

1) | With version “J” → “N” instead of “N9” | |

2) | For data regarding the seawater-resistant version refer to data sheet 29115-M | |

3) | For version "J" = seawater-resistant only "K31" | |

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | ||

4 | WRZ | ‒ | 7X | / | 6E | G24 | * |

01 | 4 main ports | 4 |

02 | Proportional directional valve with electro-hydraulic operation and external electronics | WRZ |

03 | Size 10 | 10 |

Size 16 | 16 | |

Size 25 | 25 | |

Size 32 | 32 | |

Size 52 | 52 | |

04 | Symbols; for the possible version, see "Symbols/Circuit diagrams" | E; E1-; E3-; W6-; W8-; W9-; EA; W6A |

Rated flow NG10 | ||

05 | 25 l/min | 25 |

50 l/min | 50 | |

90 l/min | 85 | |

Rated flow NG16 | ||

05 | 100 l/min | 100 |

125 l/min | 125 | |

150 l/min | 150 | |

180 l/min | 180 | |

Rated flow NG25 | ||

05 | 220 l/min | 220 |

325 l/min | 325 | |

Rated flow NG32 | ||

05 | 360 l/min | 360 |

520 l/min | 520 | |

Rated flow NG52 | ||

05 | 1000 l/min | 1000 |

06 | Component series 70 ... 79 (70 ... 79: unchanged installation and connection dimensions) | 7X |

07 | For subplate mounting | no code |

For flange connection (only NG 52) | F | |

08 | Pilot control valve NG6 | 6E |

09 | Supply voltage 24 V | G24 |

10 | Without manual override | no code |

With concealed manual override | N9 1) | |

11 | Without special type of protection | no code |

Sea water-resistant | J 2) | |

Pilot oil supply and return | ||

12 | External pilot oil supply, external pilot oil return | no code |

Internal pilot oil supply, external pilot oil return | E | |

Pilot oil supply internal, pilot oil return internal | ET | |

External pilot oil supply, internal pilot oil return | T | |

Electrical connection | ||

13 | Without mating connector, with connector according to DIN EN 175301-803, separate order | K43) |

Without mating connector, connector according to DIN EN 175201-804 | K31 3) | |

14 | Without pressure reducing valve | no code |

With pressure reducing valve ZDR 6 DP0-4X/40YM-W80 (fixedly set) | D3 | |

15 | NBR seals | M |

FKM seals | V | |

16 | Further details in the plain text | * |

1) | With version “J” → “N” instead of “N9” | |

2) | For data regarding the seawater-resistant version refer to data sheet 29115-M | |

3) | For version "J" = seawater-resistant only "K31" | |

Type | 4WRZ | ||||||

Size | 10 | 16 | 25 | 32 | 52 | ||

Installation position | any, preferably horizontal | ||||||

Ambient temperature range | °C | -20 … +70 | |||||

Storage temperature range | °C | -20 … +80 | |||||

Weight | For subplate mounting | kg | 7.8 | 11.9 | 18.2 | 42.2 | 79.5 |

for flange connection | kg | 77.5 | |||||

with "D3" | kg | 8.3 | 12.4 | 18.7 | 42.7 | 80 | |

Sine test according to DIN EN 60068-2-6 | 10 cycles, 10…2000.. 10 Hz with logarithmic frequency changing speed of 1 octave/min, 5 to 57 Hz, amplitude 1.5 mm (p-p), 57 to 2000 Hz, amplitude 10g, 3 axes | ||||||

Noise test according to DIN EN 60068-2-64 | 20…2000 Hz, amplitude 0.05g2/Hz (10gRMS) 3 axes, testing time 30 min per axis | ||||||

Shock test according to DIN EN 60068-2-27 | Half-sine 15g / 11 ms, 3 times in positive and 3 times in negative direction per axis, 3 axes | ||||||

Damp heat according to DIN EN 60068-2-30 | Variant 2: +25 °C … +55 °C, 90 % … 97 % relative humidity, 2 cycles á 24 hours | ||||||

Size | 10 | 16 | 25 | 32 | 52 | |||

Maximum operating pressure | bar | 315 | 350 | |||||

Operating pressure range | External pilot oil supply | bar | 30 … 100 | 20 … 100 | ||||

Pilot control valve without "D3", internal pilot oil return | bar | 30 … 100 | ||||||

Internal pilot oil supply | bar | 100 … 315 | 100 … 350 | |||||

Maximum return flow pressure | Port T and R, external pilot oil return | bar | 315 | 250 | 150 | 250 | ||

Port T, internal pilot oil return | bar | 30 | ||||||

Port Y | bar | 30 | ||||||

Maximum flow | l/min | 170 | 460 | 870 | 1600 | 2800 | ||

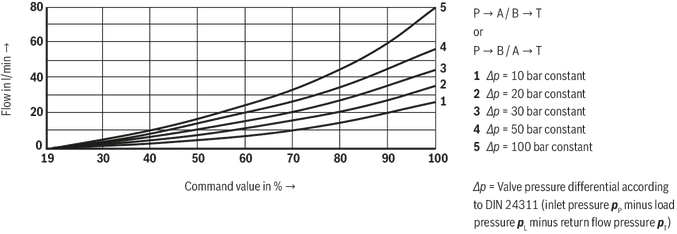

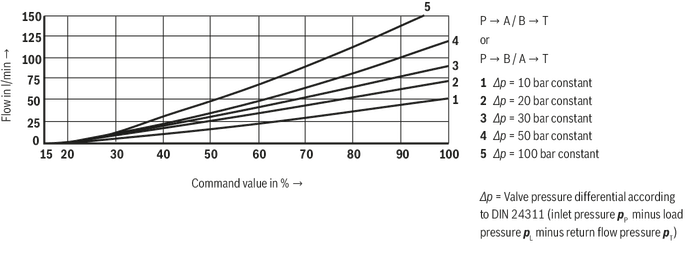

Nominal flow | l/min | 25 50 85 | 100 125 150 180 | 220 325 | 360 520 | 1000 | ||

Pilot flow | input signal 0 → 100% | Port X and Y | l/min | 3.5 | 5.5 | 7 | 15.9 | 7 |

Pilot volume | switching process 0 → 100% | cm³ | 1.7 | 4.6 | 10 | 26.5 | 54.3 | |

Hydraulic fluid temperature range | °C | -20 … +80 | ||||||

preferably | °C | -40 … +50 | ||||||

Viscosity range | mm²/s | 20 … 380 | ||||||

preferably | mm²/s | 30 … 46 | ||||||

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) | Pilot control valve | Class 18/16/13 according to ISO 4406 (c) | ||||||

Main valve | Class 20/18/15 according to ISO 4406 (c) | |||||||

Hysteresis | % | ≤ 6 | ||||||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Size | 10 | 16 | 25 | 32 | 52 | ||

Voltage type | Direct voltage | ||||||

Command value overlap | % | 15 | |||||

Maximum solenoid current | A | 1.5 | |||||

Solenoid coil resistance | Cold value at 20 °C | Ω | 4.8 | ||||

Maximum hot value | Ω | 7.2 | |||||

Actuated time | % | 100 | |||||

Maximum coil temperature 1) | °C | + 150 | |||||

Protection class according to DIN EN 60529 | IP65 (If a suitable and a correctly mounted mating connector are used.) | ||||||

Power supply | V | 24 | |||||

Supply voltage range | V | 19,4 … 35 | |||||

| 1) | Due to the surface temperatures occurring at the solenoid coils, the European standards ISO 13732-1 and EN 982 need to be adhered to. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards |

Mineral oils and related hydrocarbons | HL, HLP | NBR / FKM | DIN 51524 |

Flame-resistant - containing water | HFC (Fuchs HYDROTHERM 46M, Petrofer Ultra Safe 620) | NBR | ISO 12922 |

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids please contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The flash point of the process and operating medium used must be 40 K over the maximum solenoid surface temperature. Flame-resistant - containing water: | |||

Type | 4WRZ | ||||||

Size | 10 | 16 | 25 | 32 | 52 | ||

Installation position | any, preferably horizontal | ||||||

Ambient temperature range | °C | -20 … +70 | |||||

Storage temperature range | °C | -20 … +80 | |||||

Weight | For subplate mounting | kg | 7.8 | 11.9 | 18.2 | 42.2 | 79.5 |

for flange connection | kg | 77.5 | |||||

with "D3" | kg | 8.3 | 12.4 | 18.7 | 42.7 | 80 | |

Sine test according to DIN EN 60068-2-6 | 10 cycles, 10…2000.. 10 Hz with logarithmic frequency changing speed of 1 octave/min, 5 to 57 Hz, amplitude 1.5 mm (p-p), 57 to 2000 Hz, amplitude 10g, 3 axes | ||||||

Noise test according to DIN EN 60068-2-64 | 20…2000 Hz, amplitude 0.05g2/Hz (10gRMS) 3 axes, testing time 30 min per axis | ||||||

Shock test according to DIN EN 60068-2-27 | Half-sine 15g / 11 ms, 3 times in positive and 3 times in negative direction per axis, 3 axes | ||||||

Damp heat according to DIN EN 60068-2-30 | Variant 2: +25 °C … +55 °C, 90 % … 97 % relative humidity, 2 cycles á 24 hours | ||||||

Size | 10 | 16 | 25 | 32 | 52 | |||

Maximum operating pressure | bar | 315 | 350 | |||||

Operating pressure range | External pilot oil supply | bar | 30 … 100 | 20 … 100 | ||||

Pilot control valve without "D3", internal pilot oil return | bar | 30 … 100 | ||||||

Internal pilot oil supply | bar | 100 … 315 | 100 … 350 | |||||

Maximum return flow pressure | Port T and R, external pilot oil return | bar | 315 | 250 | 150 | 250 | ||

Port T, internal pilot oil return | bar | 30 | ||||||

Port Y | bar | 30 | ||||||

Maximum flow | l/min | 170 | 460 | 870 | 1600 | 2800 | ||

Nominal flow | l/min | 25 50 85 | 100 125 150 180 | 220 325 | 360 520 | 1000 | ||

Pilot flow | input signal 0 → 100% | Port X and Y | l/min | 3.5 | 5.5 | 7 | 15.9 | 7 |

Pilot volume | switching process 0 → 100% | cm³ | 1.7 | 4.6 | 10 | 26.5 | 54.3 | |

Hydraulic fluid temperature range | °C | -20 … +80 | ||||||

preferably | °C | -40 … +50 | ||||||

Viscosity range | mm²/s | 20 … 380 | ||||||

preferably | mm²/s | 30 … 46 | ||||||

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) | Pilot control valve | Class 18/16/13 according to ISO 4406 (c) | ||||||

Main valve | Class 20/18/15 according to ISO 4406 (c) | |||||||

Hysteresis | % | ≤ 6 | ||||||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Size | 10 | 16 | 25 | 32 | 52 | ||

Voltage type | Direct voltage | ||||||

Command value overlap | % | 15 | |||||

Maximum solenoid current | A | 1.5 | |||||

Solenoid coil resistance | Cold value at 20 °C | Ω | 4.8 | ||||

Maximum hot value | Ω | 7.2 | |||||

Actuated time | % | 100 | |||||

Maximum coil temperature 1) | °C | + 150 | |||||

Protection class according to DIN EN 60529 | IP65 (If a suitable and a correctly mounted mating connector are used.) | ||||||

Power supply | V | 24 | |||||

Supply voltage range | V | 19,4 … 35 | |||||

| 1) | Due to the surface temperatures occurring at the solenoid coils, the European standards ISO 13732-1 and EN 982 need to be adhered to. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards |

Mineral oils and related hydrocarbons | HL, HLP | NBR / FKM | DIN 51524 |

Flame-resistant - containing water | HFC (Fuchs HYDROTHERM 46M, Petrofer Ultra Safe 620) | NBR | ISO 12922 |

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids please contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The flash point of the process and operating medium used must be 40 K over the maximum solenoid surface temperature. Flame-resistant - containing water: | |||

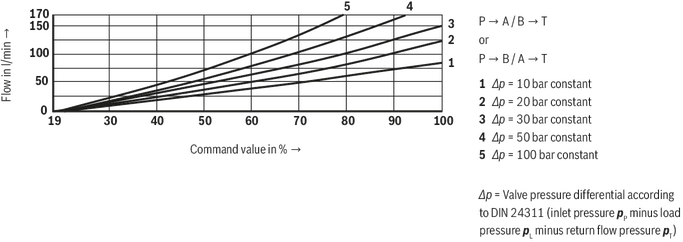

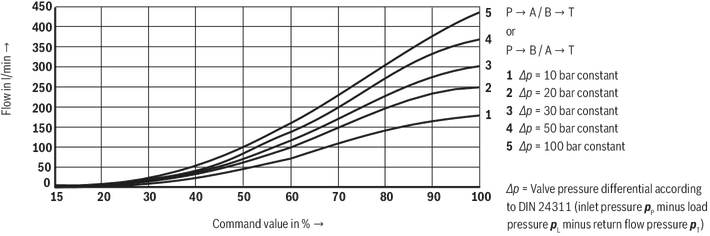

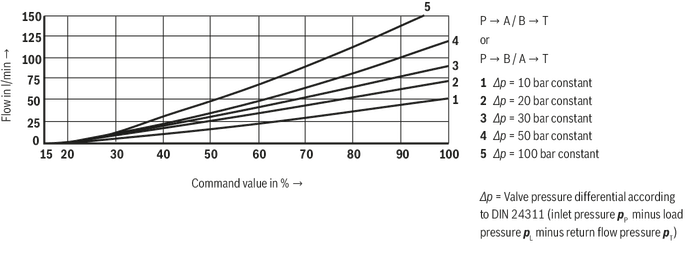

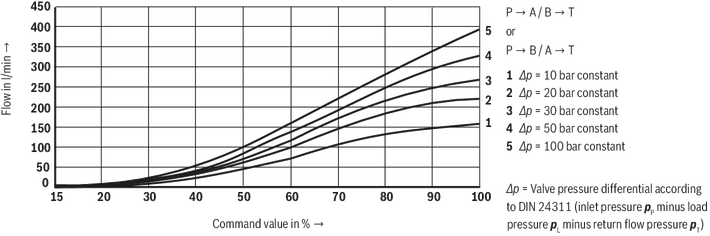

Size 10

Size 10

Size 10

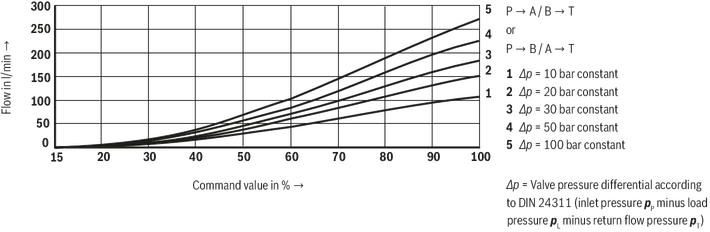

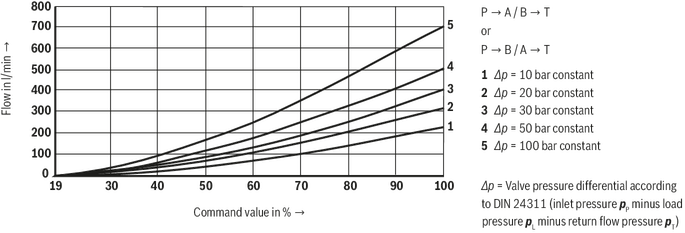

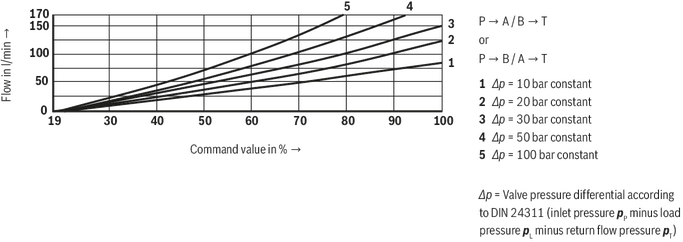

Size 16

Size 16

Size 16

Size 16

Size 16

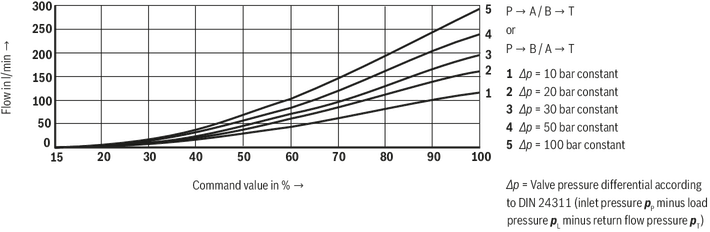

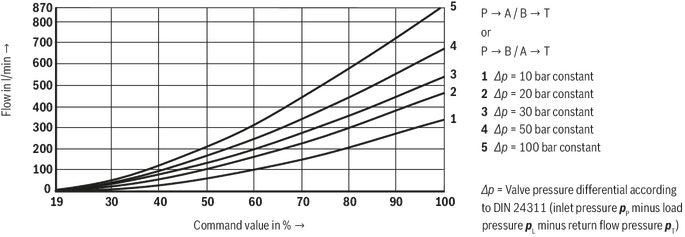

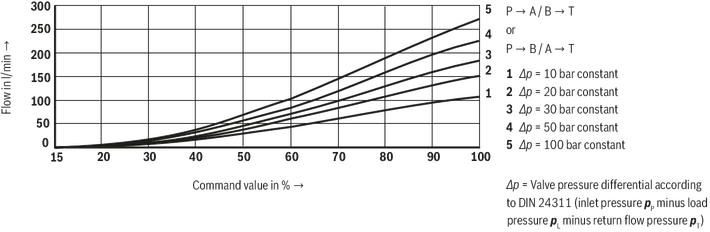

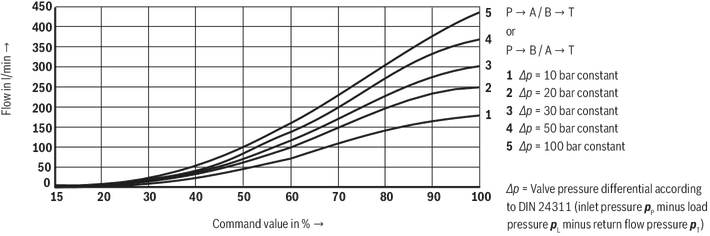

NG25

NG25

NG25

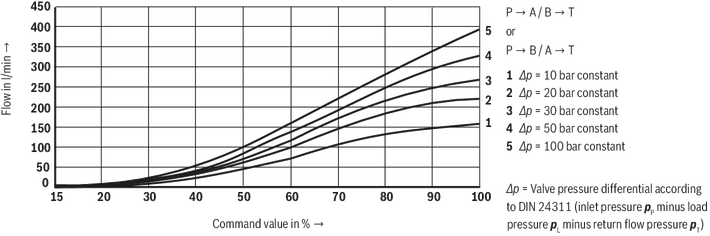

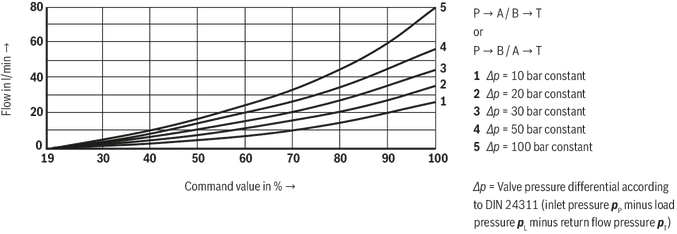

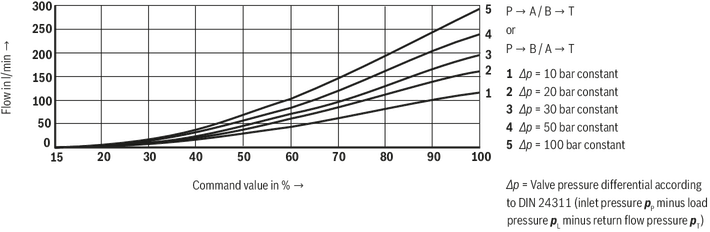

Size 32

Size 32

Size 32

NG52

NG52

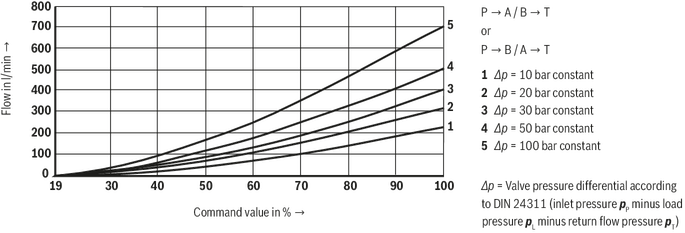

Size 10

Size 10

Size 10

Size 16

Size 16

Size 16

Size 16

Size 16

NG25

NG25

NG25

Size 32

Size 32

Size 32

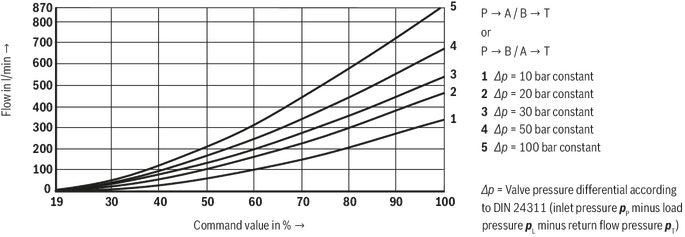

NG52

NG52