| Availability: | |

|---|---|

| Quantity: | |

4WE 6 J7X/HG24N9K4

Rexroth

R901089241

4/3-, 4/2- or 3/2-way version

Standard version

Porting pattern according to DIN 24340, form A

Wet-pin DC solenoids

Solenoid coil can be rotated

The coil can be changed without having to open the pressure-tight chamber

Electrical connection as individual connection

Concealed manual override

4/3-, 4/2- or 3/2-way version

Standard version

Porting pattern according to DIN 24340, form A

Wet-pin DC solenoids

Solenoid coil can be rotated

The coil can be changed without having to open the pressure-tight chamber

Electrical connection as individual connection

Concealed manual override

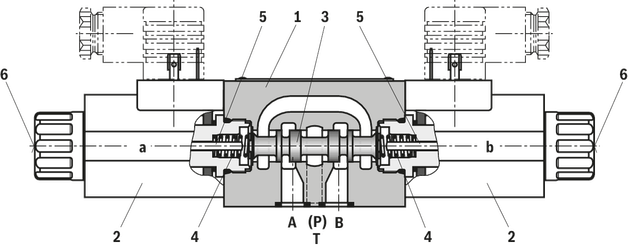

Directional valves of type WE are solenoid-actuated directional spool valves. They control the start, stop and direction of a flow.

The directional valves basically consist of the housing (1), one or two solenoids (2), the control spool (3), and one or two return springs (4). In the de-energized condition, control spool (3) is held in the central position or in the initial position by the return springs (4). The control spool (3) is actuated by wet-pin solenoids (2).

To ensure proper functioning, make sure that the pressure chamber of the solenoid is filled with oil!

The force of the solenoid (2) acts via the plunger (5) on the control spool (3) and pushes the latter from its rest position to the required end position. In this way, the required direction of flow according to the symbol is released. After de-excitation of the solenoid (2), the return spring (4) pushes the control spool (3) back to its rest position.

The manual override (6) allows control spool (3) to be moved without solenoid energization.

Type 4WE 6 E7X/H…

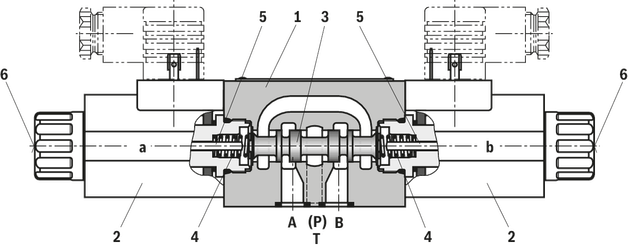

Directional valves of type WE are solenoid-actuated directional spool valves. They control the start, stop and direction of a flow.

The directional valves basically consist of the housing (1), one or two solenoids (2), the control spool (3), and one or two return springs (4). In the de-energized condition, control spool (3) is held in the central position or in the initial position by the return springs (4). The control spool (3) is actuated by wet-pin solenoids (2).

To ensure proper functioning, make sure that the pressure chamber of the solenoid is filled with oil!

The force of the solenoid (2) acts via the plunger (5) on the control spool (3) and pushes the latter from its rest position to the required end position. In this way, the required direction of flow according to the symbol is released. After de-excitation of the solenoid (2), the return spring (4) pushes the control spool (3) back to its rest position.

The manual override (6) allows control spool (3) to be moved without solenoid energization.

Type 4WE 6 E7X/H…

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | ||

WE | 6 | 7X | / | H | N9 | / | * |

01 | 3 main ports | 3 |

4 main ports | 4 | |

02 | Directional valve | WE |

03 | Size 6 | 6 |

04 | Symbols e. g. D, E etc.; possible design see Symbols | |

05 | Component series 70 … 79 (70 … 79: unchanged installation and mounting dimensions) | 7X |

06 | With spring return | no code |

Without spring return with detent | OF1) | |

07 | Standard solenoid wet (wet-pin) | H |

08 | Direct voltage 12 V | G12 |

Direct voltage 24 V | G24 | |

09 | With concealed manual override | N9 |

Electrical connection | ||

10 | Individual connection | |

Without mating connector, with connector DIN EN 175301-803 | K42) | |

Without mating connector, with connector AMP Junior-Timer | C4Z 2) | |

Seal material | ||

11 | NBR seals | no code |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | ||

12 | Further details in the plain text | * |

| 1) Only symbol D | |

| 2) Mating connectors, separate order, see data sheet 08006. |

Preferred types and standard units arecontained in the EPS (standard price list).

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | ||

WE | 6 | 7X | / | H | N9 | / | * |

01 | 3 main ports | 3 |

4 main ports | 4 | |

02 | Directional valve | WE |

03 | Size 6 | 6 |

04 | Symbols e. g. D, E etc.; possible design see Symbols | |

05 | Component series 70 … 79 (70 … 79: unchanged installation and mounting dimensions) | 7X |

06 | With spring return | no code |

Without spring return with detent | OF1) | |

07 | Standard solenoid wet (wet-pin) | H |

08 | Direct voltage 12 V | G12 |

Direct voltage 24 V | G24 | |

09 | With concealed manual override | N9 |

Electrical connection | ||

10 | Individual connection | |

Without mating connector, with connector DIN EN 175301-803 | K42) | |

Without mating connector, with connector AMP Junior-Timer | C4Z 2) | |

Seal material | ||

11 | NBR seals | no code |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | ||

12 | Further details in the plain text | * |

| 1) Only symbol D | |

| 2) Mating connectors, separate order, see data sheet 08006. |

Preferred types and standard units arecontained in the EPS (standard price list).

Size | 6 | ||

Weight (approx.) | Valve with one solenoid | kg | 1.25 |

Valve with two solenoids | kg | 1.6 | |

Installation position | any | ||

Ambient temperature range | °C | -30 … +50 | |

Size | 6 | ||

Maximum operating pressure | Port P | bar | 315 |

Port A | bar | 315 | |

Port B | bar | 315 | |

Port T 1) | bar | 160 | |

Maximum flow | l/min | 60 | |

Hydraulic fluid | see table | ||

Hydraulic fluid temperature range | °C | -30 … +80 | |

Viscosity range | mm²/s | 2.8 … 500 | |

Maximum admissible degree of contamination of the hydraulic fluid 2) | Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | With symbols A and B, port T must be used as leakage oil connection if the operating pressure exceeds the admissible tank pressure. |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | |

Mineral oils | HL, HLP, HLPD, HVLP, HVLPD | NBR, FKM | DIN 51524 | |

Bio-degradable | Insoluble in water | HETG | NBR, FKM | VDMA 24568 |

HEES | FKM | |||

Soluble in water | HEPG | FKM | VDMA 24568 | |

Containing water | Water-free | HFDU, HFDR | FKM | ISO 12922 |

Containing water | HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620 ) | NBR, HNBR | ISO 12922 | |

Important information on hydraulic fluids! For further information and data on the use of other hydraulic fluids, please refer to data sheet 90220 or contact us! There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.)! The flash point of the hydraulic fluid used must be 40 K higher than the maximum solenoid surface temperature. Flame-resistant – containing water: Maximum pressure differential per control edge 50 bar. Pressure pre-loading at the tank port >20% of the pressure differential; otherwise, increased cavitation Life cycle compared to operation with mineral oil HL, HLP 50 to 100 % Bio-degradable: When using bio-degradable hydraulic fluids that are zinc-solving, zinc may accumulate in the fluid (700 mg zinc per pole tube) | ||||

Notices!

Only actuate the manual override using a rounded tool (Ø3+1 mm) or special tool (separate order, material no. R900024943)!

Actuation of the manual override only up to a tank pressure 50 bar.

When the manual override is blocked, the actuation of the solenoid must be prevented!

The simultaneous actuation of the solenoids must be prevented!

In the electrical connection, the protective earthing conductor (PE, grounded) is to be connected in accordance with the stipulations.

Voltage type | Direct voltage | ||

Available voltages | V | 12 / 24 | |

Voltage tolerance (nominal voltage) | % | ± 10 | |

Power consumption | W | 26 | |

Duty cycle | % | 100 | |

Maximum coil temperature 1) | °C | 150 | |

Switching time according to ISO 6403 | ON | ms | 20 … 45 |

OFF | ms | 10 … 25 | |

Maximum switching frequency | 1/h | 15000 | |

Protection class according to EN 60529 | IP65 (If a suitable and a correctly mounted mating connector are used.) | ||

Insulation class VDE 0580 | F | ||

| 1) | Due to the high surface temperatures of the solenoid coils >50 °C, the standards ISO 13732-1 and ISO 4413 must be adhered and the coils must be equipped with contact protection, if required. |

Size | 6 | ||

Weight (approx.) | Valve with one solenoid | kg | 1.25 |

Valve with two solenoids | kg | 1.6 | |

Installation position | any | ||

Ambient temperature range | °C | -30 … +50 | |

Size | 6 | ||

Maximum operating pressure | Port P | bar | 315 |

Port A | bar | 315 | |

Port B | bar | 315 | |

Port T 1) | bar | 160 | |

Maximum flow | l/min | 60 | |

Hydraulic fluid | see table | ||

Hydraulic fluid temperature range | °C | -30 … +80 | |

Viscosity range | mm²/s | 2.8 … 500 | |

Maximum admissible degree of contamination of the hydraulic fluid 2) | Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | With symbols A and B, port T must be used as leakage oil connection if the operating pressure exceeds the admissible tank pressure. |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | |

Mineral oils | HL, HLP, HLPD, HVLP, HVLPD | NBR, FKM | DIN 51524 | |

Bio-degradable | Insoluble in water | HETG | NBR, FKM | VDMA 24568 |

HEES | FKM | |||

Soluble in water | HEPG | FKM | VDMA 24568 | |

Containing water | Water-free | HFDU, HFDR | FKM | ISO 12922 |

Containing water | HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620 ) | NBR, HNBR | ISO 12922 | |

Important information on hydraulic fluids! For further information and data on the use of other hydraulic fluids, please refer to data sheet 90220 or contact us! There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.)! The flash point of the hydraulic fluid used must be 40 K higher than the maximum solenoid surface temperature. Flame-resistant – containing water: Maximum pressure differential per control edge 50 bar. Pressure pre-loading at the tank port >20% of the pressure differential; otherwise, increased cavitation Life cycle compared to operation with mineral oil HL, HLP 50 to 100 % Bio-degradable: When using bio-degradable hydraulic fluids that are zinc-solving, zinc may accumulate in the fluid (700 mg zinc per pole tube) | ||||

Notices!

Only actuate the manual override using a rounded tool (Ø3+1 mm) or special tool (separate order, material no. R900024943)!

Actuation of the manual override only up to a tank pressure 50 bar.

When the manual override is blocked, the actuation of the solenoid must be prevented!

The simultaneous actuation of the solenoids must be prevented!

In the electrical connection, the protective earthing conductor (PE, grounded) is to be connected in accordance with the stipulations.

Voltage type | Direct voltage | ||

Available voltages | V | 12 / 24 | |

Voltage tolerance (nominal voltage) | % | ± 10 | |

Power consumption | W | 26 | |

Duty cycle | % | 100 | |

Maximum coil temperature 1) | °C | 150 | |

Switching time according to ISO 6403 | ON | ms | 20 … 45 |

OFF | ms | 10 … 25 | |

Maximum switching frequency | 1/h | 15000 | |

Protection class according to EN 60529 | IP65 (If a suitable and a correctly mounted mating connector are used.) | ||

Insulation class VDE 0580 | F | ||

| 1) | Due to the high surface temperatures of the solenoid coils >50 °C, the standards ISO 13732-1 and ISO 4413 must be adhered and the coils must be equipped with contact protection, if required. |

Dimensions in mm

Required surface quality of the valve contact surface |

1.1 | Solenoid “a” |

1.2 | Solenoid “b” |

2 | Mating connector without circuitry (separate order) |

3 | Mating connector with circuitry (separate order) |

4 | Name plate |

5 | Space required to remove the mating connector |

6 | Space required to remove the coil |

7 | Mounting nut, MA = 4+1 Nm |

8 | Plug screw for valve with one solenoid |

9 | Identical seal rings for ports A, B, P, T |

10 | Porting pattern according to DIN 24340 form A |

Dimensions in mm

Required surface quality of the valve contact surface |

1.1 | Solenoid “a” |

1.2 | Solenoid “b” |

4 | Name plate |

5 | Space required to remove the mating connector |

6 | Space required to remove the coil |

7 | Mounting nut, MA = 4+1 Nm |

8 | Plug screw for valve with one solenoid |

9 | Identical seal rings for ports A, B, P, T |

10 | Porting pattern according to DIN 24340 form A |

11 | Mating connector "Junior Timer", straight (separate order, see data sheet 08006) |

12 | Mating connector "Junior Timer", angled (separate order, see data sheet 08006) |

Subplates according to data sheet 45052 (separate order)

G 341/01 (G1/4)

G 342/01 (G3/8)

G 502/01 (G1/2)

Valve mounting screws (separate order)

4 hexagon socket head cap screws ISO 4762 - M5 x 50 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 7 Nm ± 10 %,

material no. R913000064

or

4 hexagon socket head cap screws ISO 4762 - M5 x 50 - 10.9

with friction coefficient μtotal = 0.12 to 0.17 a

tightening torque MA = 8.1 Nm ± 10 % results

(not included in the Rexroth delivery range)

Dimensions in mm

Required surface quality of the valve contact surface |

1.1 | Solenoid “a” |

1.2 | Solenoid “b” |

2 | Mating connector without circuitry (separate order) |

3 | Mating connector with circuitry (separate order) |

4 | Name plate |

5 | Space required to remove the mating connector |

6 | Space required to remove the coil |

7 | Mounting nut, MA = 4+1 Nm |

8 | Plug screw for valve with one solenoid |

9 | Identical seal rings for ports A, B, P, T |

10 | Porting pattern according to DIN 24340 form A |

Dimensions in mm

Required surface quality of the valve contact surface |

1.1 | Solenoid “a” |

1.2 | Solenoid “b” |

4 | Name plate |

5 | Space required to remove the mating connector |

6 | Space required to remove the coil |

7 | Mounting nut, MA = 4+1 Nm |

8 | Plug screw for valve with one solenoid |

9 | Identical seal rings for ports A, B, P, T |

10 | Porting pattern according to DIN 24340 form A |

11 | Mating connector "Junior Timer", straight (separate order, see data sheet 08006) |

12 | Mating connector "Junior Timer", angled (separate order, see data sheet 08006) |

Subplates according to data sheet 45052 (separate order)

G 341/01 (G1/4)

G 342/01 (G3/8)

G 502/01 (G1/2)

Valve mounting screws (separate order)

4 hexagon socket head cap screws ISO 4762 - M5 x 50 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 7 Nm ± 10 %,

material no. R913000064

or

4 hexagon socket head cap screws ISO 4762 - M5 x 50 - 10.9

with friction coefficient μtotal = 0.12 to 0.17 a

tightening torque MA = 8.1 Nm ± 10 % results

(not included in the Rexroth delivery range)