| Availability: | |

|---|---|

| Quantity: | |

3DR16P5-5X/200Y/00M

Rexroth

R900916668

Valve for reduction (P to A) and limitation (A to T) of a system pressure

For subplate mounting

Porting pattern according to ISO 4401-07-07-0-05

Subplates (separate order)

4 pressure ratings

4 optional adjustment types:

• Rotary knob

• Sleeve with hexagon and protective cap

• Lockable rotary knob with scale

• Rotary knob with scale

Valve for reduction (P to A) and limitation (A to T) of a system pressure

For subplate mounting

Porting pattern according to ISO 4401-07-07-0-05

Subplates (separate order)

4 pressure ratings

4 optional adjustment types:

• Rotary knob

• Sleeve with hexagon and protective cap

• Lockable rotary knob with scale

• Rotary knob with scale

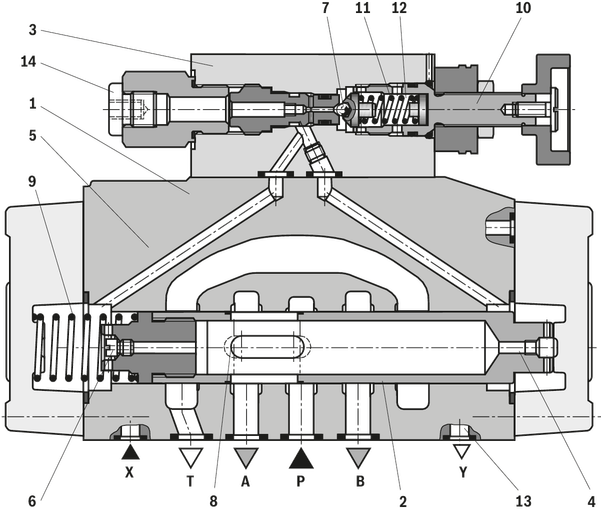

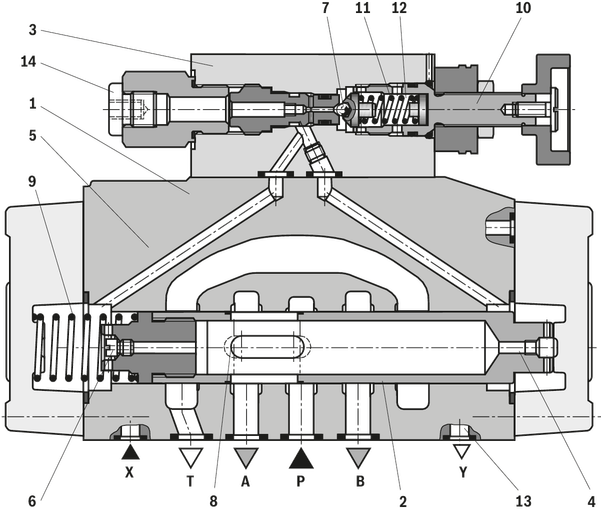

The pressure valve type 3DR is a pilot-operated 3-way pressure reducing valve with pressure limitation of the secondary circuit. It is used to reduce the system pressure.

The pressure reducing valve basically consists of the main valve (1) with control spool (2) and pilot control valve (3) with pressure adjustment type (10).

The valve is open in initial position. Hydraulic fluid can flow from channel P to channel A without restrictions. The pressure in channel A is simultaneously applied via the bore (4) at the piston area opposite the compression spring (9). Simultaneously, pressure is applied via the nozzle (6) to the spring-loaded side of the control spool (2) and via channel (5) to ball (7) in the pilot control valve (3).

Depending on the setting of the compression spring (11), pressure builds up upstream of the ball (7) and in channel (5) holding the control spool (2) in open position. Hydraulic fluid flows from channel P via the control spool (2) to channel A until a pressure builds up in channel A exceeding the pressure value set at the compression spring (11) and opening the ball (7).

The control spool (2) moves to closed position. The desired reduced pressure is reached if there is a balance between the pressure in channel A and the pressure value set at the compression spring (11).

If the pressure in channel A increases further due to an external force effect at the actuator, the control spool (2) is pushed further against the compression spring (9). In this way, channel A is connected to channel T via the control edge (8) at the control spool (2). So much hydraulic fluid is discharged into the tank that the pressure does not increase any further.

The pilot oil return from the spring chamber (12) is always realized externally via the control line (13) at port Y. A depressurized connection to the tank must always be ensured.

The pressure gauge connection (14) enables control of the reduced pressure in channel A.

The pressure valve type 3DR is a pilot-operated 3-way pressure reducing valve with pressure limitation of the secondary circuit. It is used to reduce the system pressure.

The pressure reducing valve basically consists of the main valve (1) with control spool (2) and pilot control valve (3) with pressure adjustment type (10).

The valve is open in initial position. Hydraulic fluid can flow from channel P to channel A without restrictions. The pressure in channel A is simultaneously applied via the bore (4) at the piston area opposite the compression spring (9). Simultaneously, pressure is applied via the nozzle (6) to the spring-loaded side of the control spool (2) and via channel (5) to ball (7) in the pilot control valve (3).

Depending on the setting of the compression spring (11), pressure builds up upstream of the ball (7) and in channel (5) holding the control spool (2) in open position. Hydraulic fluid flows from channel P via the control spool (2) to channel A until a pressure builds up in channel A exceeding the pressure value set at the compression spring (11) and opening the ball (7).

The control spool (2) moves to closed position. The desired reduced pressure is reached if there is a balance between the pressure in channel A and the pressure value set at the compression spring (11).

If the pressure in channel A increases further due to an external force effect at the actuator, the control spool (2) is pushed further against the compression spring (9). In this way, channel A is connected to channel T via the control edge (8) at the control spool (2). So much hydraulic fluid is discharged into the tank that the pressure does not increase any further.

The pilot oil return from the spring chamber (12) is always realized externally via the control line (13) at port Y. A depressurized connection to the tank must always be ensured.

The pressure gauge connection (14) enables control of the reduced pressure in channel A.

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | |||

3DR | 16 | P | – | 5X | / | Y | / | 00 | * |

01 | 3-way pressure reducing valve | 3DR |

02 | Size 16 | 16 |

03 | Subplate mounting | P |

Adjustment types | ||

04 | Rotary knob | 4 |

Sleeve with hexagon and protective cap | 5 | |

Lockable rotary knob with scale | 6 1) | |

Rotary knob with scale | 7 | |

05 | Component series 50 … 59 (50 … 59: unchanged installation and connection dimensions) | 5X |

06 | Set pressure up to 50 bar | 50 |

Set pressure up to 100 bar | 100 | |

Set pressure up to 200 bar | 200 | |

Set pressure up to 250 bar | 250 | |

Pilot oil flow | ||

07 | Internal pilot oil supply, external pilot oil return | Y |

08 | With stroke limitation | 00 |

Seal material | ||

09 | NBR seals | M |

FKM seals (other seals upon request) | V | |

Observe compatibility of seals with hydraulic fluid used. | ||

10 | Further details in the plain text | * |

| 1) H-key with material no. R900008158 is included in the scope of delivery |

Preferred types and standard units are specified in the EPS (standard price list).

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | |||

3DR | 16 | P | – | 5X | / | Y | / | 00 | * |

01 | 3-way pressure reducing valve | 3DR |

02 | Size 16 | 16 |

03 | Subplate mounting | P |

Adjustment types | ||

04 | Rotary knob | 4 |

Sleeve with hexagon and protective cap | 5 | |

Lockable rotary knob with scale | 6 1) | |

Rotary knob with scale | 7 | |

05 | Component series 50 … 59 (50 … 59: unchanged installation and connection dimensions) | 5X |

06 | Set pressure up to 50 bar | 50 |

Set pressure up to 100 bar | 100 | |

Set pressure up to 200 bar | 200 | |

Set pressure up to 250 bar | 250 | |

Pilot oil flow | ||

07 | Internal pilot oil supply, external pilot oil return | Y |

08 | With stroke limitation | 00 |

Seal material | ||

09 | NBR seals | M |

FKM seals (other seals upon request) | V | |

Observe compatibility of seals with hydraulic fluid used. | ||

10 | Further details in the plain text | * |

| 1) H-key with material no. R900008158 is included in the scope of delivery |

Preferred types and standard units are specified in the EPS (standard price list).

Size | 16 | |

Weight | kg | 8 |

Installation position | any | |

Ambient temperature range | °C | -30 … +50 |

Size | 16 | ||

Nominal pressure | bar | 315 | |

Maximum operating pressure | Port P | bar | 315 |

Anschluss A | bar | 250 | |

Port Y | separate and depressurized to the tank | ||

Set pressure | Minimum | flow-dependent, see "characteristic curves" | |

Maximum | bar | 50 100 200 315 | |

Maximum flow | l/min | 220 | |

Hydraulic fluid | see table | ||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Viscosity range | mm²/s | 10 … 800 | |

Maximum admissible degree of contamination of the hydraulic fluid | Class 9 according to NAS 1638. For this, we recommend using a filter with a minimum retention rate of β10 ≥ 75. | ||

Hydraulic fluid | Classification | Suitable sealing materials | Standards | |

Mineral oil | HL, HLP | FKM, NBR | DIN 51524 | |

Bio-degradable | Insoluble in water | HEES (synthetic esters) | FKM | VDMA 24568 |

HETG (rape seed oil) | FKM, NBR | |||

Soluble in water | HEPG (polyglycols) | FKM | VDMA 24568 | |

Other hydraulic fluids on request | ||||

Size | 16 | |

Weight | kg | 8 |

Installation position | any | |

Ambient temperature range | °C | -30 … +50 |

Size | 16 | ||

Nominal pressure | bar | 315 | |

Maximum operating pressure | Port P | bar | 315 |

Anschluss A | bar | 250 | |

Port Y | separate and depressurized to the tank | ||

Set pressure | Minimum | flow-dependent, see "characteristic curves" | |

Maximum | bar | 50 100 200 315 | |

Maximum flow | l/min | 220 | |

Hydraulic fluid | see table | ||

Hydraulic fluid temperature range | NBR seals | °C | -30 … +80 |

FKM seals | °C | -20 … +80 | |

Viscosity range | mm²/s | 10 … 800 | |

Maximum admissible degree of contamination of the hydraulic fluid | Class 9 according to NAS 1638. For this, we recommend using a filter with a minimum retention rate of β10 ≥ 75. | ||

Hydraulic fluid | Classification | Suitable sealing materials | Standards | |

Mineral oil | HL, HLP | FKM, NBR | DIN 51524 | |

Bio-degradable | Insoluble in water | HEES (synthetic esters) | FKM | VDMA 24568 |

HETG (rape seed oil) | FKM, NBR | |||

Soluble in water | HEPG (polyglycols) | FKM | VDMA 24568 | |

Other hydraulic fluids on request | ||||

Dimensions in mm

1 | Name plate |

2 | Pilot control valve |

3 | Main valve |

4 | Adjustment type "5" |

5 | Hexagon SW10 |

6 | Adjustment type "4" |

7 | Adjustment type "6" |

8 | Adjustment type "7" |

9 | Seal rings for ports X, Y, and L |

10 | Seal rings for ports A, B, P, and T |

11 | Port X must be closed in the subplate |

12 | Ports B and L must be closed in the subplate |

13 | Pressure gauge connection |

14 | Valve contact surface, porting pattern according to ISO 4401-07-07-0-05 |

15 | Space required to remove the key |

Subplates (separate order)

G172/01 (G3/4)

G174/01 (G1)

Valve mounting screws (separate order)

4 hexagon socket head cap screws

ISO 4762 - M10 x 60 - 10.9-flZn-240h-L

Friction coefficient µtotal = 0.09 to 0.14,

Tightening torque MA = 73 Nm ± 10 %,

material no. R913000116

2 hexagon socket head cap screws

ISO 4762 - M6 x 60 - 10.9-flZn-240h-L

Friction coefficient µtotal = 0.09 to 0.14,

Tightening torque MA = 15,5 Nm ± 10 %,

material no. R913000115

Notice:

The specified tightening torques stated are guidelines when using screws with the specified friction coefficients and when using a manual torque wrench (tolerance ± 10%).

Dimensions in mm

1 | Name plate |

2 | Pilot control valve |

3 | Main valve |

4 | Adjustment type "5" |

5 | Hexagon SW10 |

6 | Adjustment type "4" |

7 | Adjustment type "6" |

8 | Adjustment type "7" |

9 | Seal rings for ports X, Y, and L |

10 | Seal rings for ports A, B, P, and T |

11 | Port X must be closed in the subplate |

12 | Ports B and L must be closed in the subplate |

13 | Pressure gauge connection |

14 | Valve contact surface, porting pattern according to ISO 4401-07-07-0-05 |

15 | Space required to remove the key |

Subplates (separate order)

G172/01 (G3/4)

G174/01 (G1)

Valve mounting screws (separate order)

4 hexagon socket head cap screws

ISO 4762 - M10 x 60 - 10.9-flZn-240h-L

Friction coefficient µtotal = 0.09 to 0.14,

Tightening torque MA = 73 Nm ± 10 %,

material no. R913000116

2 hexagon socket head cap screws

ISO 4762 - M6 x 60 - 10.9-flZn-240h-L

Friction coefficient µtotal = 0.09 to 0.14,

Tightening torque MA = 15,5 Nm ± 10 %,

material no. R913000115

Notice:

The specified tightening torques stated are guidelines when using screws with the specified friction coefficients and when using a manual torque wrench (tolerance ± 10%).