| Availability: | |

|---|---|

| Quantity: | |

2FRE 6 A-2X/10QK4MV

Rexroth

R900937860

2-way version

Valve with pressure compensator for pressure-compensated controlling of a flow

Controlled by proportional solenoid

For subplate mounting: Porting pattern according to ISO 4401-03-02-0-05

With electrical position control for the metering orifice

Axially movable position transducer coil, therefore an easy zero point calibration of the metering orifice is possible without having to interfere with the control electronics (electrical-hydraulic)

Low manufacturing tolerance of the valve and electric amplifier VT-VRPA1-150-1X (analog) and amplifier module VT-MRPA1-150-1X (analog), optional

Flow control in both directions through rectifier sandwich plate

2-way version

Valve with pressure compensator for pressure-compensated controlling of a flow

Controlled by proportional solenoid

For subplate mounting: Porting pattern according to ISO 4401-03-02-0-05

With electrical position control for the metering orifice

Axially movable position transducer coil, therefore an easy zero point calibration of the metering orifice is possible without having to interfere with the control electronics (electrical-hydraulic)

Low manufacturing tolerance of the valve and electric amplifier VT-VRPA1-150-1X (analog) and amplifier module VT-MRPA1-150-1X (analog), optional

Flow control in both directions through rectifier sandwich plate

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | ||

2FRE | 6 | - | 2X | / | K4 | V | * |

01 | Proportional flow control valve in 2-way version | 2FRE | |

02 | Size 6 | 6 | |

03 | With external closing of the pressure compensator (suppression of the start-up jump) | A | |

Without external closing of the pressure compensator | B | ||

04 | Component series 20 ... 29 (20 ... 29: unchanged installation and connection dimensions) | 2X | |

rated flow A → B, flow characteristic | |||

05 | Linear | Up to 1 l/min | 1L |

Up to 2 l/min | 2L | ||

Up to 8 l/min | 8L | ||

Progressive | Up to 3 l/min | 3Q | |

Up to 6 l/min | 6Q | ||

Up to 10 l/min | 10Q | ||

Up to 16 l/min | 16Q | ||

Up to 25 l/min | 25Q | ||

Progressive with rapid traverse | Fine control range up to 2 l/min | 2QE | |

Electrical connection | |||

06 | Individual connection | ||

Without mating connector, connector DIN EN 175301-803-A (proportional solenoid) and GSA20 (position transducer) | K41) | ||

07 | With check valve | R | |

Without check valve | M | ||

Seal material | |||

08 | FKM seals | V | |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | |||

09 | Further details in the plain text | * | |

| 1) | Mating connectors, separate order, see "Accessories" and datasheet 08006. |

01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | ||

2FRE | 6 | - | 2X | / | K4 | V | * |

01 | Proportional flow control valve in 2-way version | 2FRE | |

02 | Size 6 | 6 | |

03 | With external closing of the pressure compensator (suppression of the start-up jump) | A | |

Without external closing of the pressure compensator | B | ||

04 | Component series 20 ... 29 (20 ... 29: unchanged installation and connection dimensions) | 2X | |

rated flow A → B, flow characteristic | |||

05 | Linear | Up to 1 l/min | 1L |

Up to 2 l/min | 2L | ||

Up to 8 l/min | 8L | ||

Progressive | Up to 3 l/min | 3Q | |

Up to 6 l/min | 6Q | ||

Up to 10 l/min | 10Q | ||

Up to 16 l/min | 16Q | ||

Up to 25 l/min | 25Q | ||

Progressive with rapid traverse | Fine control range up to 2 l/min | 2QE | |

Electrical connection | |||

06 | Individual connection | ||

Without mating connector, connector DIN EN 175301-803-A (proportional solenoid) and GSA20 (position transducer) | K41) | ||

07 | With check valve | R | |

Without check valve | M | ||

Seal material | |||

08 | FKM seals | V | |

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) | |||

09 | Further details in the plain text | * | |

| 1) | Mating connectors, separate order, see "Accessories" and datasheet 08006. |

Size | 6 | |

Component series | 2X | |

Installation position | Any | |

Weight | kg | 1.8 |

Storage temperature range | °C | -20 … +80 |

Ambient temperature range | °C | -20 … +50 |

Size | 6 | ||

Maximum operating pressure | Anschluss A | bar | 210 |

Minimum pressure differential | bar | 6 … 10 | |

Pressure differential with free return flow B → A | See characteristic curve | ||

Pressure/flow-dependence of input/output pressure | See characteristic curve | ||

Temperature drift | See characteristic curve | ||

Hydraulic fluid | see table | ||

Hydraulic fluid temperature range | °C | -20 … +80 | |

Viscosity range | mm²/s | 15 … 380 | |

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) | Class 20/18/15 according to ISO 4406 (c) | ||

Hysteresis | of qVmax | % | < ± 1 |

Repetition accuracy | of qVmax | % | < 1 |

Manufacturing tolerance | at command value 33 % | % | ≤ ± 3 |

at command value 100 % | % | ≤ ± 5 | |

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Version | 1L | 2L | 8L | 3Q | 6Q | 10Q | 16Q | 25Q | 2QE | ||

Maximum flow | l/min | 1 | 2 | 8 | 3 | 6 | 10 | 16 | 25 | ||

Minimum flow | 100 bar | ml/min | 25 | 50 | 15 | 25 | 50 | 70 | 100 | 15 | |

210 bar | ml/min | 25 | 50 | 25 | 50 | 70 | 100 | 25 | |||

Maximum leakage flow, Δp A → B with a command value of 0% 1) | 50 bar | ml/min | 4 | 6 | 4 | 6 | 7 | 10 | 4 | ||

100 bar | ml/min | 5 | 8 | 5 | 8 | 10 | 15 | 5 | |||

210 bar | ml/min | 7 | 12 | 7 | 12 | 15 | 22 | 7 | |||

| 1) | Measured with ν = 41 mm2/s and ϑ = 50 °C |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet |

Mineral oils | HL, HLP | FKM | DIN 51524 | 90220 |

Flame-resistant - water-free | HFDU (glycol base) | FKM | ISO 12922 | 90222 |

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids please contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The ignition temperature of the hydraulic fluid used must be 50 K higher than the maximum surface temperature. | ||||

Voltage type | Direct voltage | ||

Maximum current per solenoid | A | 1.5 | |

Coil resistance | Cold value at 20 °C | Ω | 5.4 |

Maximum hot value | Ω | 8.2 | |

Duty cycle | % | 100 | |

Electrical connection 1) | Connector according to DIN EN 175301-803-A | ||

Protection class according to DIN EN 60529 2) | IP65 (If a suitable and a correctly mounted mating connector are used.) | ||

| 1) | Mating connector, separate order |

| 2) | Due to the arising surface temperatures of the solenoid coils, the standards ISO 13732-1 and ISO 4413 are to be observed. |

Coil resistance at 20°C | Total resistance between 1 and 2 | Ω | 31.5 |

Total resistance between 2 and PE | Ω | 45.5 | |

Total resistance between PE and 1 | Ω | 31.5 | |

Electrical connection 1) | Connector GSA20 | ||

Type of protection according to EN 60529 2) | IP65 (If a suitable and a correctly mounted mating connector are used.) | ||

Inductivity | mH | 6 ... 8 | |

Oscillator frequency | kHz | 2.5 | |

Electrical position measurement system | Differential throttle | ||

Nominal stroke | mm | 3.5 | |

| 1) | Mating connector, separate order |

| 2) | Due to the arising surface temperatures of the solenoid coils, the standards ISO 13732-1 and ISO 4413 are to be observed. |

Size | 6 | |

Component series | 2X | |

Installation position | Any | |

Weight | kg | 1.8 |

Storage temperature range | °C | -20 … +80 |

Ambient temperature range | °C | -20 … +50 |

Size | 6 | ||

Maximum operating pressure | Anschluss A | bar | 210 |

Minimum pressure differential | bar | 6 … 10 | |

Pressure differential with free return flow B → A | See characteristic curve | ||

Pressure/flow-dependence of input/output pressure | See characteristic curve | ||

Temperature drift | See characteristic curve | ||

Hydraulic fluid | see table | ||

Hydraulic fluid temperature range | °C | -20 … +80 | |

Viscosity range | mm²/s | 15 … 380 | |

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) | Class 20/18/15 according to ISO 4406 (c) | ||

Hysteresis | of qVmax | % | < ± 1 |

Repetition accuracy | of qVmax | % | < 1 |

Manufacturing tolerance | at command value 33 % | % | ≤ ± 3 |

at command value 100 % | % | ≤ ± 5 | |

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Version | 1L | 2L | 8L | 3Q | 6Q | 10Q | 16Q | 25Q | 2QE | ||

Maximum flow | l/min | 1 | 2 | 8 | 3 | 6 | 10 | 16 | 25 | ||

Minimum flow | 100 bar | ml/min | 25 | 50 | 15 | 25 | 50 | 70 | 100 | 15 | |

210 bar | ml/min | 25 | 50 | 25 | 50 | 70 | 100 | 25 | |||

Maximum leakage flow, Δp A → B with a command value of 0% 1) | 50 bar | ml/min | 4 | 6 | 4 | 6 | 7 | 10 | 4 | ||

100 bar | ml/min | 5 | 8 | 5 | 8 | 10 | 15 | 5 | |||

210 bar | ml/min | 7 | 12 | 7 | 12 | 15 | 22 | 7 | |||

| 1) | Measured with ν = 41 mm2/s and ϑ = 50 °C |

Hydraulic fluid | Classification | Suitable sealing materials | Standards | Data sheet |

Mineral oils | HL, HLP | FKM | DIN 51524 | 90220 |

Flame-resistant - water-free | HFDU (glycol base) | FKM | ISO 12922 | 90222 |

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids please contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The ignition temperature of the hydraulic fluid used must be 50 K higher than the maximum surface temperature. | ||||

Voltage type | Direct voltage | ||

Maximum current per solenoid | A | 1.5 | |

Coil resistance | Cold value at 20 °C | Ω | 5.4 |

Maximum hot value | Ω | 8.2 | |

Duty cycle | % | 100 | |

Electrical connection 1) | Connector according to DIN EN 175301-803-A | ||

Protection class according to DIN EN 60529 2) | IP65 (If a suitable and a correctly mounted mating connector are used.) | ||

| 1) | Mating connector, separate order |

| 2) | Due to the arising surface temperatures of the solenoid coils, the standards ISO 13732-1 and ISO 4413 are to be observed. |

Coil resistance at 20°C | Total resistance between 1 and 2 | Ω | 31.5 |

Total resistance between 2 and PE | Ω | 45.5 | |

Total resistance between PE and 1 | Ω | 31.5 | |

Electrical connection 1) | Connector GSA20 | ||

Type of protection according to EN 60529 2) | IP65 (If a suitable and a correctly mounted mating connector are used.) | ||

Inductivity | mH | 6 ... 8 | |

Oscillator frequency | kHz | 2.5 | |

Electrical position measurement system | Differential throttle | ||

Nominal stroke | mm | 3.5 | |

| 1) | Mating connector, separate order |

| 2) | Due to the arising surface temperatures of the solenoid coils, the standards ISO 13732-1 and ISO 4413 are to be observed. |

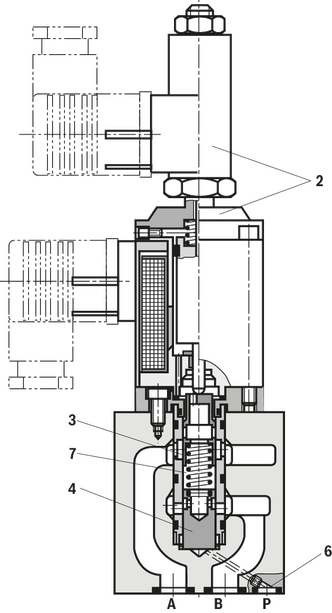

Dimensions in mm

|

Required surface quality of the valve contact surface |

1 | Valve housing |

2 | Proportional solenoid with inductive position transducer |

3.1 | Mating connector for proportional solenoid, separate order |

3.2 | Mating connector for position transducer, separate order |

4 | Space required to remove the mating connector |

5 | Name plate |

6.1 | Identical seal rings for ports A, B, P and blind counterbore |

7 | |

8 | Port B |

9 | Blind counterbore Ø 12.6 mm |

10 | Machined valve contact surface; Porting pattern according to ISO 4401-03-02-0-05 |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Subplates (separate order) with porting pattern according to ISO 4401-03-02-0-05, see data sheet 45100.

4 hexagon socket head cap screws ISO 4762 - M5 x 30 - 10.9-flZn-240h-L

(friction coefficient 0.09 … 0.14 according to VDA 235-101)

Tightening torque MA = 7 Nm ± 10 %, material no. R913048086

or

4 hexagon socket head cap screws ISO 4762 - M5 x 30 - 10.9

(friction coefficient 0.08 … 0.16 according to VDI 2230 – black)

Tightening torque MA = 8.1 Nm ± 10 %, material no. 2910150205

Rectifier sandwich plate impossible in proportional flow control valve, version “A” (with external closing of the pressure compensator).

The dimensions are nominal dimensions which are subject to tolerances.

Dimensions in mm

|

Required surface quality of the valve contact surface |

1 | Valve housing |

2 | Proportional solenoid with inductive position transducer |

3.1 | Mating connector for proportional solenoid, separate order |

3.2 | Mating connector for position transducer, separate order |

4 | Space required to remove the mating connector |

5 | Name plate |

6.1 | Identical seal rings for ports A, B, P and blind counterbore |

7 | |

8 | Port B |

9 | Blind counterbore Ø 12.6 mm |

10 | Machined valve contact surface; Porting pattern according to ISO 4401-03-02-0-05 |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Subplates (separate order) with porting pattern according to ISO 4401-03-02-0-05, see data sheet 45100.

4 hexagon socket head cap screws ISO 4762 - M5 x 30 - 10.9-flZn-240h-L

(friction coefficient 0.09 … 0.14 according to VDA 235-101)

Tightening torque MA = 7 Nm ± 10 %, material no. R913048086

or

4 hexagon socket head cap screws ISO 4762 - M5 x 30 - 10.9

(friction coefficient 0.08 … 0.16 according to VDI 2230 – black)

Tightening torque MA = 8.1 Nm ± 10 %, material no. 2910150205

Rectifier sandwich plate impossible in proportional flow control valve, version “A” (with external closing of the pressure compensator).

The dimensions are nominal dimensions which are subject to tolerances.

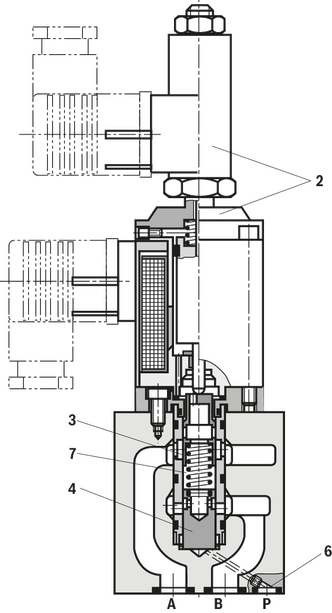

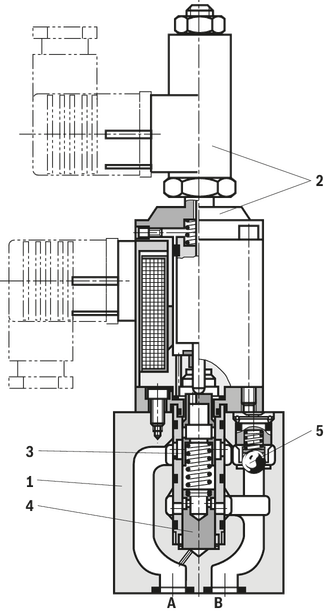

Proportional flow control valves of the 2FRE ... type comprise a 2-way function. They are capable of controlling a flow indicated by the electrical command value in a pressure- and temperature-compensated manner.

The set-up basically consists of a housing (1), proportional solenoid with inductive position transducer (2), metering orifice (3), pressure compensator (4) as well as check valve (5), optional.

The flow setting is determined by the indication (0 to 100%) at the command value potentiometer. Via the amplifier as well as the proportional solenoid, the indicated command value has an effect on the adjustment of the metering orifice (3). The position of the metering orifice (3) is recorded by the inductive position transducer. Any existing variations from the command value are corrected by the position control.

The pressure compensator (4) keeps the pressure drop at the metering orifice (3) at a constant value at all times. Thus, the flow is load-compensated.

The low temperature drift is the result of the favorable design of the metering orifice. With command value 0%, the metering orifice is closed. In the event of a power failure or cable break at the inductive position transducer, the metering orifice closes.

From the command value 0%, a smooth start-up is possible. Via two ramps in the electric amplifier, the metering orifice can be opened and closed with delay.

Via the check valve (5), a free return flow from B to A is possible. With an additional rectifier sandwich plate of the Z4S 6... type under the proportional flow control valve, the supply and return flow from the actuator can be regulated.

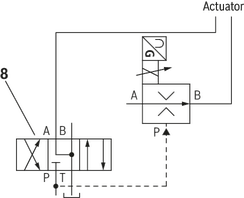

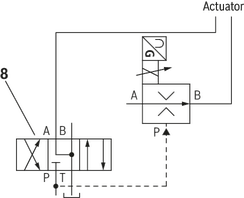

The function of this valve is basically the same as that of valve type "B...RV".

For the start-up jump suppression with open metering orifice (3) (command value > 0%), a closing of the pressure compensator (4) is provided via port P (6). The internal connection between port A and the pressure compensator (4) is abandoned. Via the external port P (6), the pressure in P upstream to the directional valve (8) has an impact on the pressure compensator (4) and keeps the latter in its closed position against the spring force (7). If the directional valve (8) is switched from P to B, the pressure compensator (4) moves from the closed position into the control position and the start-up jump is thus prevented.

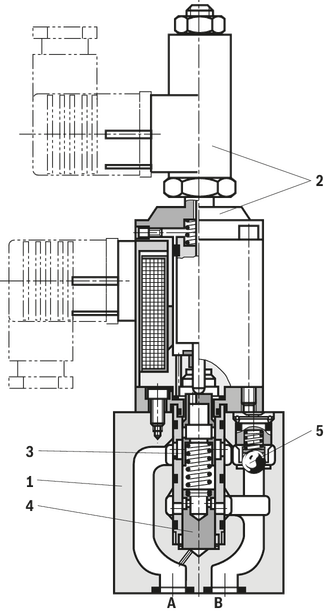

Proportional flow control valves of the 2FRE ... type comprise a 2-way function. They are capable of controlling a flow indicated by the electrical command value in a pressure- and temperature-compensated manner.

The set-up basically consists of a housing (1), proportional solenoid with inductive position transducer (2), metering orifice (3), pressure compensator (4) as well as check valve (5), optional.

The flow setting is determined by the indication (0 to 100%) at the command value potentiometer. Via the amplifier as well as the proportional solenoid, the indicated command value has an effect on the adjustment of the metering orifice (3). The position of the metering orifice (3) is recorded by the inductive position transducer. Any existing variations from the command value are corrected by the position control.

The pressure compensator (4) keeps the pressure drop at the metering orifice (3) at a constant value at all times. Thus, the flow is load-compensated.

The low temperature drift is the result of the favorable design of the metering orifice. With command value 0%, the metering orifice is closed. In the event of a power failure or cable break at the inductive position transducer, the metering orifice closes.

From the command value 0%, a smooth start-up is possible. Via two ramps in the electric amplifier, the metering orifice can be opened and closed with delay.

Via the check valve (5), a free return flow from B to A is possible. With an additional rectifier sandwich plate of the Z4S 6... type under the proportional flow control valve, the supply and return flow from the actuator can be regulated.

The function of this valve is basically the same as that of valve type "B...RV".

For the start-up jump suppression with open metering orifice (3) (command value > 0%), a closing of the pressure compensator (4) is provided via port P (6). The internal connection between port A and the pressure compensator (4) is abandoned. Via the external port P (6), the pressure in P upstream to the directional valve (8) has an impact on the pressure compensator (4) and keeps the latter in its closed position against the spring force (7). If the directional valve (8) is switched from P to B, the pressure compensator (4) moves from the closed position into the control position and the start-up jump is thus prevented.